Nov. . 11, 2024 06:55 Back to list

tio2 rutile type factories

The Rise of TiO2 Rutile Type Factories A Critical Look

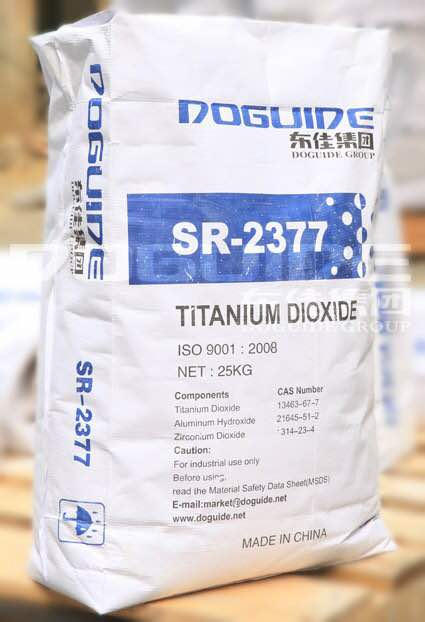

Titanium dioxide (TiO2) is a white pigment that has gained universal acceptance in various industries, ranging from consumer goods to construction materials. Among the different crystalline forms of TiO2, rutile is regarded as the most valuable due to its superior properties, such as greater opacity and durability. The demand for rutile-type TiO2 has prompted a significant increase in the number of factories dedicated to its production. This trend not only showcases technological advancements but also raises questions regarding environmental sustainability and market dynamics.

The Importance of TiO2 Rutile

Rutile TiO2 is highly preferred in the production of paint, coatings, plastics, cosmetics, and food products, among others. Its significance stems from its ability to scatter light effectively and protect materials from UV degradation. This makes rutile an essential component in applications where durability and brightness are critical. Furthermore, its non-toxic nature enhances its appeal, particularly in the food and cosmetic sectors.

The global market for TiO2 is expected to experience substantial growth, driven by increased demand in emerging markets and robust growth in existing markets. As construction activities accelerate globally, the need for high-quality paints and coatings is leading to greater consumption of rutile TiO2. According to market analysis, the overall TiO2 market size is projected to reach over $25 billion by 2027, highlighting the lucrative opportunities for manufacturers.

The Manufacturing Process of Rutile TiO2

The production of rutile TiO2 can be achieved through various methods. The most common process involves the sulfate and chloride methods. The sulfate method is well-developed and utilizes titanium ore, such as ilmenite, which is processed with sulfuric acid. In contrast, the chloride process is considered more efficient and environmentally friendly since it employs titanium-rich minerals and produces fewer waste products.

With advancements in technology, many factories are implementing innovative production techniques that maximize efficiency and reduce environmental impact. The shift towards greener processes not only meets regulatory standards but also aligns with growing consumer demand for sustainable products. Investments in research and development have enabled manufacturers to optimize their processes, yielding high-purity rutile in a cost-effective manner.

tio2 rutile type factories

Environmental Considerations

Despite the benefits, the rise in rutile TiO2 factories has raised environmental and ethical concerns. The extraction and processing of titanium ore can result in significant ecological degradation if not managed responsibly. Deforestation, soil erosion, and water contamination are potential consequences of mining activities. Furthermore, the chemical processes involved in TiO2 production can lead to the release of harmful substances if stringent controls are not implemented.

The industry is under pressure to adopt more sustainable practices. Many companies are transitioning to cleaner technologies and implementing circular economy principles to mitigate their environmental footprint. The development of closed-loop systems for production waste and continuous monitoring of emissions are steps being taken to promote sustainability.

Market Dynamics and Future Trends

As demand for rutile TiO2 continues to grow, the market landscape is transforming. New players are entering the industry, increasing competition and driving innovation. Producers are not only focused on scaling their operations but also on enhancing product quality and diversifying their offerings to cater to niche markets.

Moreover, geopolitical factors may influence TiO2 supply chains. Many titanium ores are found in politically sensitive regions, which can create volatility in supply and pricing. Companies must remain agile, adapting to changes in trade policies and seeking alternative sources of raw materials to ensure business continuity.

Conclusion

The establishment of TiO2 rutile type factories represents a significant development in the materials manufacturing landscape. While the potential for economic growth is substantial, it is crucial for the industry to prioritize environmental stewardship and sustainable practices. As we look to the future, balancing economic interests with ecological responsibility will be key in shaping the success and longevity of TiO2 production. The path forward must involve collaboration among manufacturers, governments, and consumers to foster an industry that not only meets growing demands but also protects the planet for future generations.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025