Okt . 10, 2024 04:37 Back to list

High-Quality Titanium Dioxide Powder Manufacturing Facility for Various Applications

The Evolution of TiO2 Powder Factories A Journey through Innovation

Titanium dioxide (TiO2) powder has emerged as a crucial material in various industries, including paint, coatings, plastics, and cosmetics. The manufacturing of TiO2 powder has seen significant advancements over the years, driven by technological innovation and increasing demand for high-performance products. In this article, we delve into the evolution of TiO2 powder factories and explore how they have adapted to changing market needs.

The Evolution of TiO2 Powder Factories A Journey through Innovation

Modern TiO2 powder factories now utilize advanced technologies that enhance product quality and minimize environmental impact. Innovations in processing equipment, such as improved reactors and filtration systems, have streamlined production workflows. Moreover, automation and real-time monitoring have become integral in ensuring consistency and precision in TiO2 powder manufacturing.

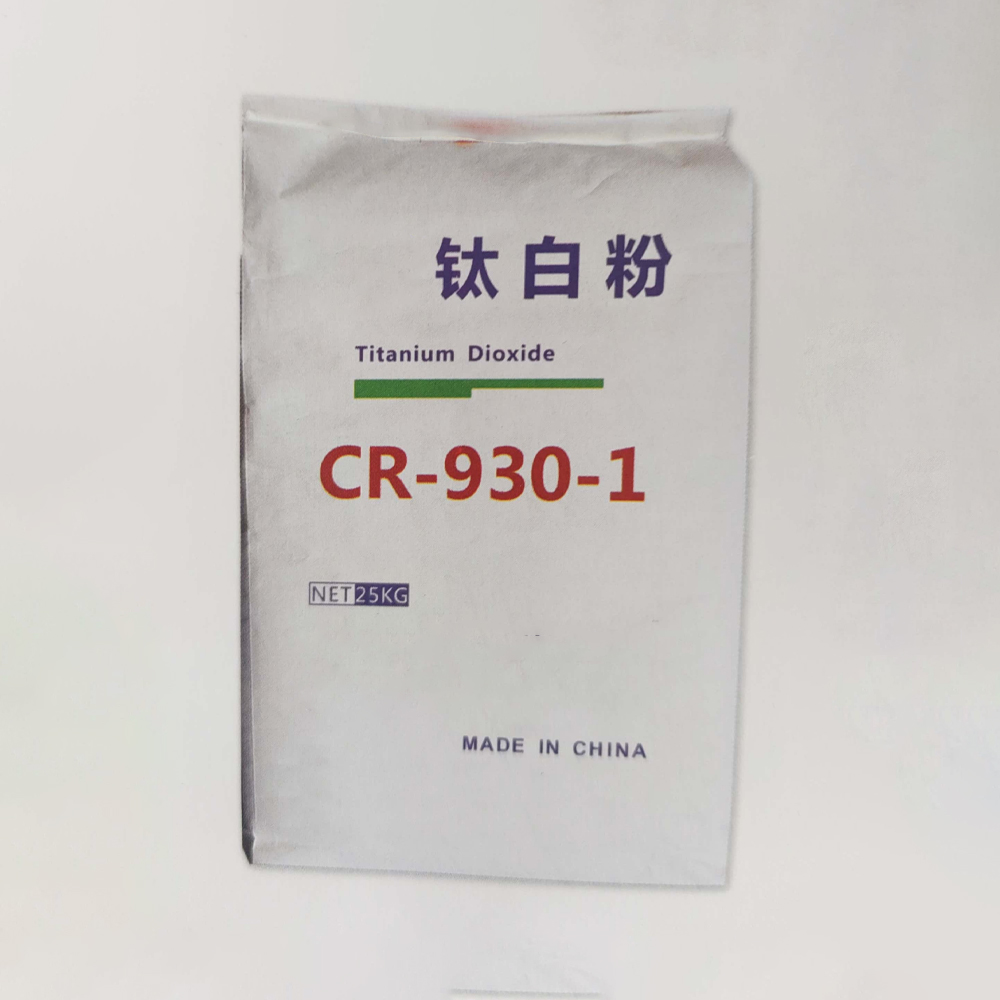

tio2 powder factory

Another driving force behind the transformation of TiO2 powder factories is the growing demand for environmentally friendly and sustainable products. Manufacturers are increasingly focusing on developing less harmful formulations and finding ways to recycle by-products. This has not only improved the sustainability of production processes but has also opened up new market opportunities for specialty TiO2 products.

The market for TiO2 powder continues to expand globally, with emerging economies leading the charge in consumption. The construction and automotive industries, in particular, have been significant consumers of TiO2 for applications like paints and coatings that require exceptional durability and opacity. As these industries evolve, TiO2 powder factories must remain agile, continuously adapting to the latest trends and customer requirements.

In conclusion, the journey of TiO2 powder factories reflects a remarkable evolution influenced by technological innovations, regulatory changes, and market dynamics. As the demand for high-quality, sustainable TiO2 products grows, these factories must continue to innovate and adapt. The future of TiO2 production looks promising, driven by commitment to environmental stewardship and customer satisfaction, ensuring that it remains a vital component in numerous applications across industries.

-

Top 13463-67-7 Titanium Dioxide Coating Supplier | High-Grade Rutile

NewsAug.23,2025

-

R960 TiO2: High-Performance Pigment for Brightness & Durability

NewsAug.22,2025

-

Trusted Titania TiO2 Supplier & Manufacturer | Quality Bulk TiO2

NewsAug.11,2025

-

Premium Titanium Dioxide: High Purity Pigment & UV Blocker

NewsAug.10,2025

-

Rutile Titanium Dioxide for Paint Factories: Premium Industrial Grade Tio2

NewsAug.09,2025

-

Premium Titania TiO2 Manufacturer & Supplier

NewsAug.08,2025