Dez . 11, 2024 10:46 Back to list

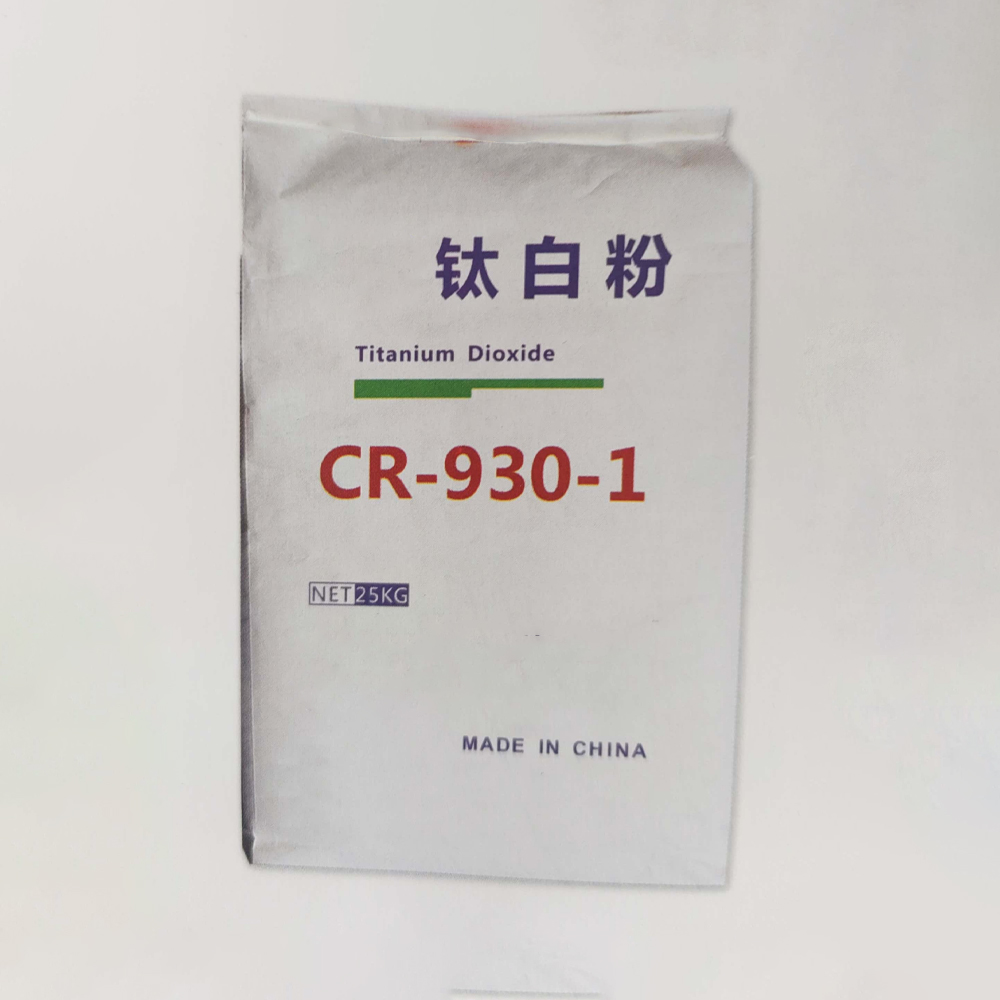

High-Quality Rutile Titanium Dioxide TiO2 Powder from Trusted Manufacturer

The Evolution of Factory-Made Rutile Titanium Dioxide Powder

Rutile titanium dioxide (TiO2) is one of the most widely-used white pigments in various industries, including paint, coatings, plastics, and cosmetics. The increasing demand for high-quality TiO2 has led to the establishment of numerous factories specializing in the production of rutile TiO2 powders. This article explores the manufacturing processes, applications, advantages, and environmental considerations associated with rutile titanium dioxide powder.

Manufacturing Process

Rutile titanium dioxide powder is produced through several stages, which involve both the extraction of raw materials and intricate processing techniques aimed at achieving the desired purity and particle size. The most common method for producing TiO2 is the sulfate process and the chloride process.

1. Sulfate Process This method involves the reaction of ilmenite (a titanium-iron oxide mineral) or titanium dioxide-rich minerals with sulfuric acid. The reaction yields titanyl sulfate, which is subsequently hydrolyzed to form titanium dioxide. This method produces lower-quality TiO2 with a greater amount of impurities.

2. Chloride Process The chloride process is favored for its ability to produce high-purity titanium dioxide with superior brightness and opacity. In this method, titanium ores are reacted with chlorine at high temperatures to produce titanium tetrachloride (TiCl4). This compound is then oxidized at elevated temperatures to yield pure rutile TiO2 powder.

Applications

Rutile titanium dioxide serves multiple functions across various industries

. Its excellent opacity, whiteness, and durability have made it the pigment of choice in- Paints and Coatings TiO2 is essential for ensuring vibrant colors and coverage, as it enhances the hiding power of paints. The durability and resistance to UV radiation also contribute to the longevity of the coatings.

- Plastics Rutile TiO2 is used in plastic products to improve opacity, brightness, and UV resistance, making it an attractive choice for outdoor applications.

factory tio2 powder rutile titanium dioxide

- Cosmetics In the cosmetic industry, TiO2 serves as a pigment in products such as foundations, sunscreens, and powders, providing not only color but also a degree of UV protection.

- Papers The paper industry utilizes TiO2 to improve brightness, opacity, and printability.

Advantages of Rutile Titanium Dioxide

The rutile form of titanium dioxide has several advantages over its counterpart, anatase. Rutile TiO2 has better light scattering properties, higher refractive index, and greater chemical stability, leading to enhanced performance in applications requiring durability and lasting power. Additionally, the consistent particle size and surface treatments applied to rutile powders optimize their performance in various formulations.

Environmental Considerations

Despite its widespread use, the production of rutile titanium dioxide raises environmental concerns. The extraction of titanium ores can lead to habitat destruction and soil degradation, while the manufacturing processes can generate waste and emissions. Moreover, to address potential toxicity associated with nanoparticles and dust, regulatory measures and sustainable practices are being developed.

To mitigate these concerns, many factories are adopting cleaner production technologies, recycling waste materials, and ensuring compliance with environmental regulations. Innovations in alternative production methods and the development of bio-based TiO2 alternatives are also being explored to minimize environmental footprints.

Conclusion

Factory-produced rutile titanium dioxide powder has become an indispensable component in many industries, attributed to its exceptional properties and versatility. As the demand for high-quality TiO2 continues to grow, the industry must address environmental challenges through sustainable practices and innovative technologies. By balancing quality production with environmental responsibility, manufacturers can ensure the continued success and acceptance of rutile titanium dioxide in the global market.

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025