снеж . 04, 2024 12:48 Back to list

ultra white paint titanium dioxide factory

The Importance of Ultra White Paint A Close Look at Titanium Dioxide Factories

In the world of paint and coatings, the quest for the perfect white has led manufacturers to develop ultra white paint formulations that not only offer a brilliant finish but also ensure durability and coverage. At the heart of these formulations lies one vital ingredient titanium dioxide (TiO2). This article explores the significance of titanium dioxide factories in producing ultra white paint, examining both the process and the impact on various industries.

What is Titanium Dioxide?

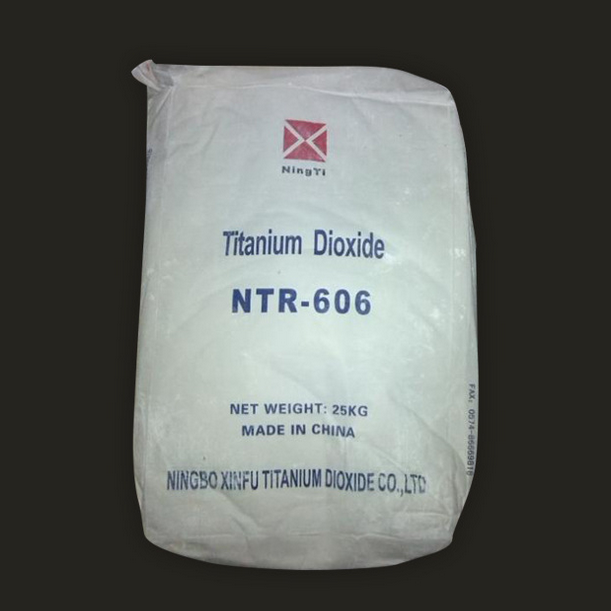

Titanium dioxide is a naturally occurring mineral that has been widely used as a white pigment. Its excellent opacity, brightness, and resistance to discoloration make it an ideal choice for creating high-quality white paint. Due to its ability to scatter light effectively, titanium dioxide can enhance the coverage of paint, requiring fewer coats for an even and vibrant finish.

There are two primary forms of titanium dioxide used in the paint industry rutile and anatase. The rutile form is preferred for ultra white paint due to its superior opacity and stability. Manufacturers often rely on sophisticated processes to extract and refine titanium dioxide from its ore, ensuring that the final product meets the demanding standards of paint applications.

The Manufacturing Process

The production of titanium dioxide is a multi-step process generally involving the extraction of titanium ore, typically from minerals such as ilmenite and rutile

. The ore undergoes a series of chemical treatments, including the sulfate and chloride processes, to produce high-purity titanium dioxide.1. Extraction The titanium ore is mined and crushed to separate the titanium content from other minerals. 2. Conversion The extracted ore is subjected to chemical reactions, either through the sulfate or chloride process. The sulfate process involves digesting the ore in sulfuric acid, while the chloride process uses chlorine gas. Both methods result in titanium tetrachloride, which is further processed into titanium dioxide.

3. Purification The impure titanium dioxide is then purified to ensure it meets industry standards. This involves removing unwanted impurities and optimizing particle size for better performance in paint formulations.

ultra white paint titanium dioxide factory

4. Drying and Milling The final titanium dioxide product is dried and milled to produce a fine powder. It is this powder that is then incorporated into paint formulations to achieve the ultra white finish.

Environmental Considerations

While titanium dioxide is praised for its properties, the manufacturing process is not without environmental concerns. The production of titanium dioxide can generate waste and emissions, necessitating responsible management practices. Many manufacturers are actively working to enhance sustainability by optimizing processes, recycling waste materials, and reducing energy consumption.

Furthermore, as awareness of environmental issues grows, the demand for eco-friendly paints has surged. This shift has prompted titanium dioxide factories to explore alternative production methods and utilize renewable resources to create sustainable, ultra white paints that align with modern consumer values.

Applications and Market Demand

The demand for ultra white paint, powered by titanium dioxide, spans various industries, including automotive, construction, and consumer goods. In architecture, for instance, ultra white coatings are favored for their reflective properties, contributing to energy efficiency by reducing cooling costs in buildings.

In the automotive sector, an ultra white finish enhances vehicle aesthetics, providing a sleek and modern appearance that attracts consumers. Similarly, in the home improvement sector, homeowners seek out ultra white paints for their interior and exterior projects, driving market growth.

Conclusion

Titanium dioxide factories play an essential role in the formulation of ultra white paint, producing a pigment that meets the high standards required by various industries. As the demand for sustainable practices continues to rise, these factories are adapting to create eco-friendly solutions, ensuring that ultra white paint remains a staple in the coatings market. The ongoing innovations in titanium dioxide production not only promise brighter and more durable paints but also a commitment to environmental responsibility, paving the way for a more sustainable future in paint manufacturing.

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025

-

High Quality Titanium Dioxide Used in Rubber – Trusted Supplier & Factory Price

NewsJul.08,2025

-

High Purity Barium Sulfate Particle Size - Wholesale Manufacturer from China

NewsJul.07,2025

-

Premium Titanium Dioxide Lomon R-996 Supplier – Quality & Wholesale Price from China

NewsJul.07,2025

-

Top Titanium Manufacturers in China - Quality Titanium Dioxide Supplier & Production Line Solutions

NewsJul.06,2025

-

OEM Titanium White Supplier & Factory – High Purity, Consistent Quality for Industrial Use

NewsJul.06,2025