Каст . 12, 2024 21:56 Back to list

Titanox Titanium Dioxide Production Facility Overview and Innovations in Manufacturing

The Titanox Titanium Dioxide Factory Pioneering Excellence in Production

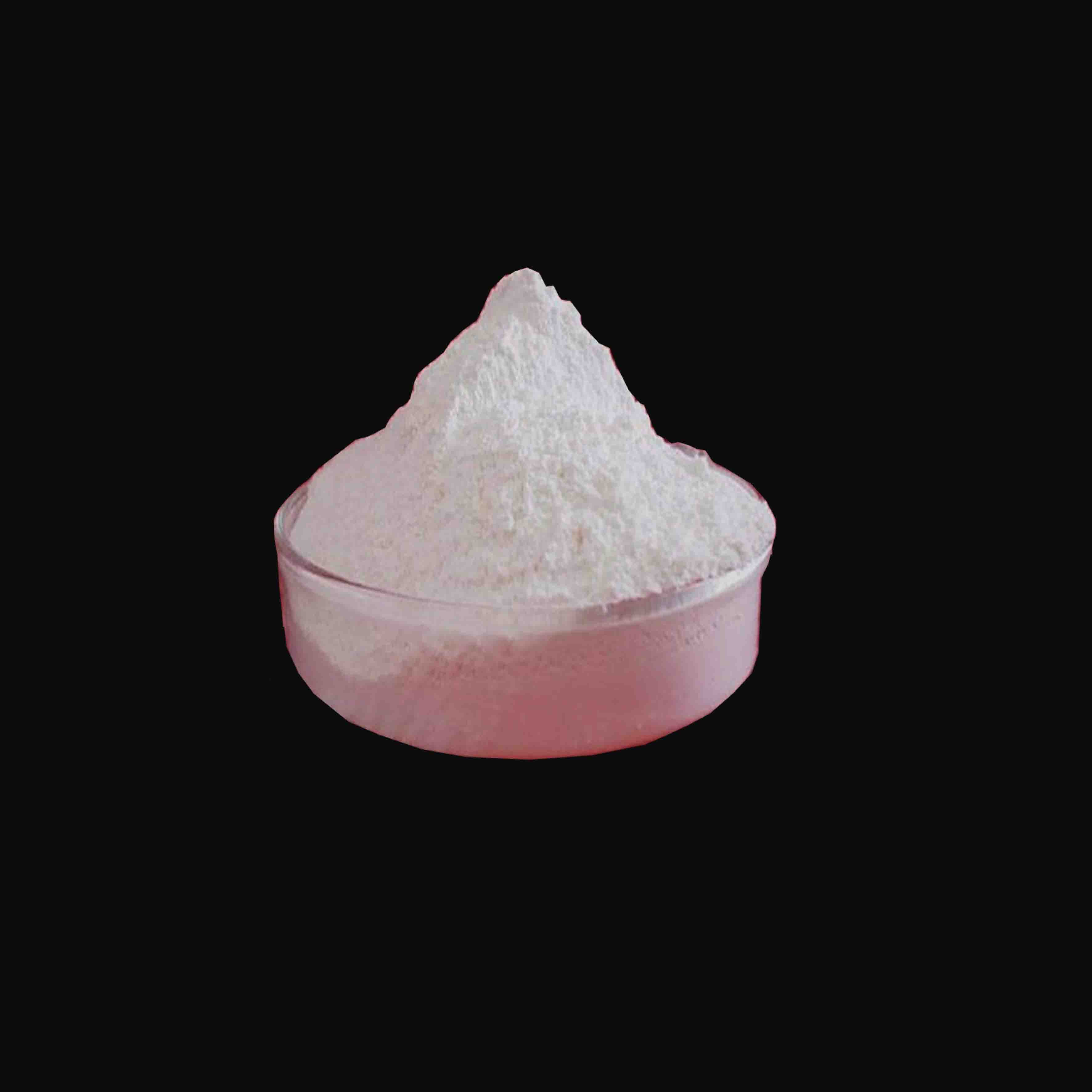

In the ever-evolving landscape of industrial manufacturing, few materials have proven as indispensable as titanium dioxide (TiO2). Renowned for its exceptional opacity, brightness, and durability, titanium dioxide is a crucial ingredient in various industries, including paints, coatings, plastics, paper, and even cosmetics. One of the leading manufacturers in this field, Titanox, has established itself as a cornerstone of quality and innovation in the production of titanium dioxide.

The Role of Titanium Dioxide

Titanium dioxide is celebrated for its remarkable properties. It serves as a white pigment, offering outstanding hiding power and UV protection. Its non-toxic nature makes it an ideal choice for consumer products, from food packaging to sunscreen. As environmental concerns continue to rise, TiO2 has gained traction as a safer alternative to other pigments that may contain harmful chemicals. This has led to increased demand, placing factories like Titanox at the forefront of supplying this essential material to meet global needs.

Titanox A Brief Overview

Located strategically to optimize logistics and supply chain efficiency, Titanox’s factory harnesses the latest advancements in titanium dioxide production technology. The facility is equipped with state-of-the-art machinery and adheres to strict environmental regulations, ensuring that the manufacturing process is not only efficient but also sustainable.

Titanox specializes in producing high-quality titanium dioxide through an integrated production process

. This includes the sulfate process and the chloride process—two extensively used methods that ensure the purity and quality of the final product.1. Sulfate Process This method involves the reaction of ilmenite (a naturally occurring mineral) with sulfuric acid. The resulting titanium sulfate is then hydrolyzed to produce titanium dioxide. This process is often favored for its ability to produce high-purity TiO2 at a relatively lower cost.

2. Chloride Process This more modern method employs chlorine to extract titanium from ore. The titanium tetrachloride produced is further processed to yield the high-performance titanium dioxide that meets stringent industry standards. Although this process is more capital-intensive, it results in a product with superior brightness and opacity.

titanox titanium dioxide factory

Commitment to Sustainability

At Titanox, environmental responsibility is a core value. The factory has implemented measures to minimize waste and reduce carbon emissions throughout its processes. By recycling materials and utilizing renewable energy sources, Titanox not only adheres to regulations but also plays a role in promoting a sustainable future. The factory actively seeks to lower its environmental footprint, ensuring that the production of titanium dioxide aligns with global sustainability goals.

Innovation and Research

Research and development (R&D) are pivotal to Titanox's success. The company continually invests in innovative technologies to improve production efficiency and product quality. By collaborating with academic institutions and industry leaders, Titanox strives to stay ahead of market trends, ensuring that its products meet the evolving needs of its clients.

The R&D team focuses on enhancing the properties of titanium dioxide. This includes developing formulations that provide greater UV protection, improved durability, and expanded application capabilities in various markets. Such innovations not only benefit Titanox but also contribute to the advancement of the titanium dioxide industry as a whole.

Conclusion

Titanox has established itself as a leader in the titanium dioxide manufacturing sector. Through its commitment to quality, sustainability, and innovation, Titanox is well-positioned to address the growing global demand for titanium dioxide. The factory’s adherence to advanced production methods and environmental responsibility reflects its dedication to providing high-performance products while safeguarding the planet.

As industries around the world continue to prioritize safer and more effective materials, Titanox stands ready to meet these challenges head-on. With a keen focus on research and development, along with a robust commitment to sustainability, Titanox not only pioneers excellence in titanium dioxide production but also sets the standard for the industry, making significant strides toward a brighter and more sustainable future.

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025