titanium dioxide in plastics manufacturers

Feb . 14, 2025 23:38 Back to list

titanium dioxide in plastics manufacturers

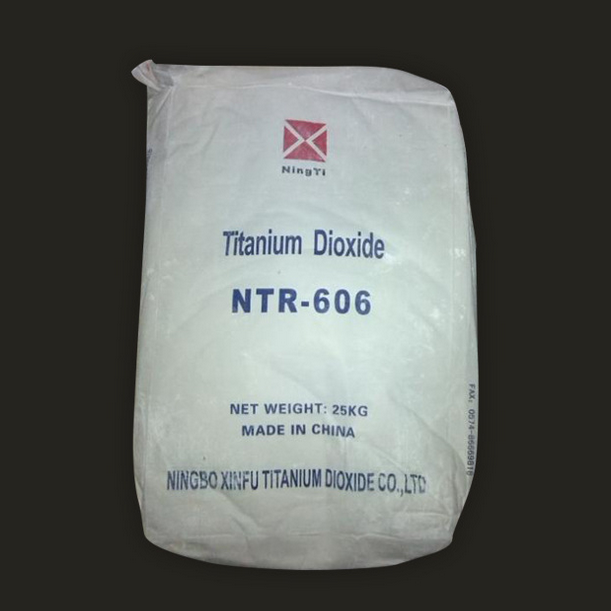

Titanium dioxide, a compound lauded for its versatility, plays a significant role in the plastics industry. As experts in the field can affirm, its applications in plastic manufacturing are substantial. This article unveils valuable insights into how titanium dioxide enhances plastic products, explores its manufacturing intricacies, and underscores its benefits, ensuring a rich tapestry of expert knowledge for industry players seeking authority in the market.

Additionally, manufacturers and suppliers of titanium dioxide in plastics are often at the forefront of innovation, developing new blends and technologies that push the boundaries of what is possible with this versatile pigment. These advancements have given rise to smart plastics with enhanced functionalities, such as increased heat resistance or improved mechanical properties, catering to the ever-evolving demands of modern applications. Trust in titanium dioxide products is also grounded in the transparency and accountability of manufacturers. Industry leaders provide comprehensive technical support, advising on product formulation and application techniques to optimize the use of titanium dioxide. This customer-centric approach not only facilitates successful product development but also builds enduring relationships with clients, empowering them with knowledge and assurance. The global landscape of titanium dioxide in plastics manufacturing is competitive, with key players investing in research and development to maintain an edge. Their efforts are aimed at reducing the environmental impact of titanium dioxide production, focusing on sustainable processes and materials that align with global environmental priorities. This sustainability lens further enhances the credibility and appeal of manufacturers who are proactive in addressing ecological concerns. For those seeking to understand the nitty-gritty of titanium dioxide in plastics, immersing in industry case studies and technical workshops offers invaluable experience. These platforms provide real-world scenarios where theoretical knowledge meets practical implementation. Understanding the challenges and solutions other manufacturers have encountered can guide new entrants in the market, providing them with a roadmap to success. In conclusion, titanium dioxide remains a cornerstone of modern plastic manufacturing, offering unmatched benefits in terms of product enhancement and durability. The intersection of technical expertise, regulatory compliance, and innovation defines the mastery of this compound within the industry. As manufacturers continue to refine their processes and products, the future of titanium dioxide in plastics promises exciting developments, further underlining its indispensability in creating high-quality, sustainable plastic solutions. Such advancements will undoubtedly continue to strengthen the trust and authority these manufacturers hold in the industrial landscape.

Additionally, manufacturers and suppliers of titanium dioxide in plastics are often at the forefront of innovation, developing new blends and technologies that push the boundaries of what is possible with this versatile pigment. These advancements have given rise to smart plastics with enhanced functionalities, such as increased heat resistance or improved mechanical properties, catering to the ever-evolving demands of modern applications. Trust in titanium dioxide products is also grounded in the transparency and accountability of manufacturers. Industry leaders provide comprehensive technical support, advising on product formulation and application techniques to optimize the use of titanium dioxide. This customer-centric approach not only facilitates successful product development but also builds enduring relationships with clients, empowering them with knowledge and assurance. The global landscape of titanium dioxide in plastics manufacturing is competitive, with key players investing in research and development to maintain an edge. Their efforts are aimed at reducing the environmental impact of titanium dioxide production, focusing on sustainable processes and materials that align with global environmental priorities. This sustainability lens further enhances the credibility and appeal of manufacturers who are proactive in addressing ecological concerns. For those seeking to understand the nitty-gritty of titanium dioxide in plastics, immersing in industry case studies and technical workshops offers invaluable experience. These platforms provide real-world scenarios where theoretical knowledge meets practical implementation. Understanding the challenges and solutions other manufacturers have encountered can guide new entrants in the market, providing them with a roadmap to success. In conclusion, titanium dioxide remains a cornerstone of modern plastic manufacturing, offering unmatched benefits in terms of product enhancement and durability. The intersection of technical expertise, regulatory compliance, and innovation defines the mastery of this compound within the industry. As manufacturers continue to refine their processes and products, the future of titanium dioxide in plastics promises exciting developments, further underlining its indispensability in creating high-quality, sustainable plastic solutions. Such advancements will undoubtedly continue to strengthen the trust and authority these manufacturers hold in the industrial landscape.

Latest news

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025