Oct . 11, 2025 00:40 Back to list

Titanium Dioxide: High Purity, Brightness & UV Shield

titanium dioxide,l titanium dioxide,titanium dioxide t,titanium dioxide e,titanium dioxide ph,titanium dioxide 12,titanium dioxide sa,ttk titanium dioxide,titanium dioxide 298,titanium dioxide use,buy titanium dioxide is a key solution in the manufacturing industry, specifically within Chemical raw material and chemical product manufacturing industry and Manufacturing of basic chemical raw materials. This article explores how Hebei Caiqing New Material Technology Co., LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- titanium dioxide,l titanium dioxide,titanium dioxide t,titanium dioxide e,titanium dioxide ph,titanium dioxide 12,titanium dioxide sa,ttk titanium dioxide,titanium dioxide 298,titanium dioxide use,buy titanium dioxide Overview

- Benefits & Use Cases of titanium dioxide,l titanium dioxide,titanium dioxide t,titanium dioxide e,titanium dioxide ph,titanium dioxide 12,titanium dioxide sa,ttk titanium dioxide,titanium dioxide 298,titanium dioxide use,buy titanium dioxide in Manufacturing of basic chemical raw materials

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on titanium dioxide,l titanium dioxide,titanium dioxide t,titanium dioxide e,titanium dioxide ph,titanium dioxide 12,titanium dioxide sa,ttk titanium dioxide,titanium dioxide 298,titanium dioxide use,buy titanium dioxide from Hebei Caiqing New Material Technology Co., LTD

titanium dioxide,l titanium dioxide,titanium dioxide t,titanium dioxide e,titanium dioxide ph,titanium dioxide 12,titanium dioxide sa,ttk titanium dioxide,titanium dioxide 298,titanium dioxide use,buy titanium dioxide Overview

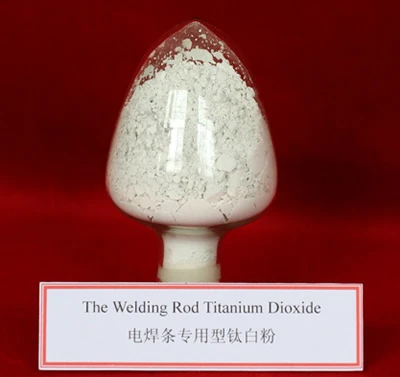

Titanium dioxide (TiO2) is a high-performance white inorganic oxide prized for its opacity, brightness, and UV durability—cornerstone properties in the Manufacturing of basic chemical raw materials. With a refractive index approaching 2.7 (rutile), TiO2 enables strong hiding power and tinting strength at low loadings, improving formulation efficiency across coatings, plastics, inks, paper, and welding electrode fluxes. In industry shorthand you’ll often see lettered and numbered designations—titanium dioxide T, titanium dioxide E, titanium dioxide SA, and titanium dioxide 298 (e.g., R-298 type)—that signal surface treatments and dispersion profiles tailored to application needs. References to “L titanium dioxide” typically align with high L whiteness, while “titanium dioxide ph” relates to stable slurry and wet-end processing behavior.

Hebei Caiqing New Material Technology Co., LTD supplies consistent TiO2 powder engineered for industrial throughput, including grades suitable for electric welding rod formulations where controlled particle size distribution and low impurity profiles aid arc stability and slag detachability. From batch-to-batch uniformity to optimized dispersibility, Hebei Caiqing helps B2B decision makers standardize quality, reduce rework, and accelerate scale-up in complex production environments.

Benefits & Use Cases of titanium dioxide,l titanium dioxide,titanium dioxide t,titanium dioxide e,titanium dioxide ph,titanium dioxide 12,titanium dioxide sa,ttk titanium dioxide,titanium dioxide 298,titanium dioxide use,buy titanium dioxide in Manufacturing of basic chemical raw materials

Within basic chemical raw materials, titanium dioxide use spans several high-volume segments: - Coatings and primers: high opacity and brightness enable thinner films with equal coverage, lowering VOC per surface area. - Plastics and masterbatch: titanium dioxide 298 or comparable grades deliver dispersion, UV shielding, and whiteness in PP, PE, PVC, and engineering resins. - Printing inks and paper: fine, well-treated particles provide gloss control and consistent optical density. - Welding electrodes: specialized TiO2 enhances slag formation/flow and bead appearance while supporting stable, spatter-minimized arcs.

Hebei Caiqing’s portfolio covers multiple treatment chemistries and rheology profiles across families that align with titanium dioxide T, titanium dioxide E, titanium dioxide SA, and titanium dioxide 12, ensuring compatibility with different resin systems, grind technologies, and pH windows (titanium dioxide ph). For OEMs evaluating ttk titanium dioxide equivalents or cross-grades, Hebei Caiqing provides application-matched alternatives with dependable dispersion, high L whiteness, and weathering resistance—key advantages that translate into lower dosage and higher throughput on industrial lines.

Cost, Maintenance & User Experience

Total cost of ownership with TiO2 hinges on effective dispersion, dosage efficiency, and line uptime. High-tint strength pigments from Hebei Caiqing typically achieve target opacity at lower loading, saving on raw material costs and reducing milling energy. Consistent particle size distribution also minimizes filter plugging and equipment wear, cutting maintenance time. In welding electrode production, stable flow and compressibility improve extrusion consistency, lowering defect rates and scrap.

B2B users report faster color development, reduced grind cycles, and fewer shade adjustments after switching to well-treated grades comparable to titanium dioxide 298 or letter-series options (titanium dioxide t/e/sa). These gains improve ROI by shortening changeovers and increasing first-pass yield. For storage and handling, Hebei Caiqing’s controlled moisture and low-dust packaging help maintain powder integrity and workplace cleanliness. Whether you’re scaling a new masterbatch line or optimizing a mature coating recipe, the user experience emphasizes predictability—critical for planners, QC managers, and procurement leaders balancing cost, quality, and delivery risk.

Sustainability & Market Trends in manufacturing

Regulatory and market pressures are pushing manufacturers toward lower-impact chemistry and higher resource efficiency. In pigments, that means maximizing opacity per kilogram, reducing energy-intensive grinding, and pursuing low-VOC, waterborne, and high-solids systems. Hebei Caiqing New Material Technology Co., LTD advances these trends with TiO2 grades engineered for fast dispersion and robust performance at reduced loadings—supporting lighter formulations without compromising coverage or durability.

Global compliance expectations (e.g., REACH registration for EU trade) and transparent supply chains are shaping procurement decisions. Hebei Caiqing emphasizes consistent quality control, traceable batches, and guidance on safe handling for powders. Market growth in infrastructure coatings, packaging films, and electrode manufacturing continues to favor resilient supply partnerships. With ongoing R&D into surface treatments, dispersion aids, and pH-stable systems (titanium dioxide ph), the company positions customers to meet next-generation performance and sustainability KPIs while maintaining competitive cost structures.

Conclusion on titanium dioxide,l titanium dioxide,titanium dioxide t,titanium dioxide e,titanium dioxide ph,titanium dioxide 12,titanium dioxide sa,ttk titanium dioxide,titanium dioxide 298,titanium dioxide use,buy titanium dioxide from Hebei Caiqing New Material Technology Co., LTD

From coatings and plastics to welding electrodes, titanium dioxide delivers unmatched opacity, whiteness, and durability. Whether you specify titanium dioxide 298, lettered families like titanium dioxide T/E/SA, or seek high L “l titanium dioxide” performance and pH stability, Hebei Caiqing New Material Technology Co., LTD offers reliable, application-ready options that elevate quality and reduce total cost. If you plan to buy titanium dioxide for industrial scale-up, partner with a supplier that understands B2B precision.

Contact us: email: sales01@cqtitaniumdioxide.com

Visit our website: https://www.cqtitaniumdioxide.com

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025