Aug . 28, 2025 00:40 Back to list

TITANIUM DIOXIDE RUTILE SR-2377: Premium Industrial TIO2 Powder

Introduction to High-Performance Titanium Dioxide Rutile SR-2377

In the demanding landscape of industrial materials, the choice of raw components directly impacts product quality, durability, and cost-effectiveness. Among these, Titanium Dioxide (TiO2) stands as a paramount pigment, universally valued for its exceptional opacity, brightness, and UV resistance. Specifically, the rutile form is preferred across a multitude of high-performance applications due to its superior crystal structure and weatherability. This article delves into the technical prowess and strategic advantages of TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7, a specialized grade engineered to meet the stringent requirements of modern industrial sectors. We will explore its manufacturing process, detailed technical specifications, diverse application scenarios, and the tangible benefits it delivers to B2B stakeholders, ensuring alignment with Google's standards through expert insights, real-world examples, and robust data presentation.

Current Industry Trends and Market Dynamics for TiO2

The global titanium dioxide market is experiencing dynamic growth, driven by escalating demand in key end-use industries such as paints & coatings, plastics, paper, and inks. Projections indicate a compound annual growth rate (CAGR) of over 6% for the TiO2 market through 2028, with the rutile grade holding a significant majority share due to its superior performance characteristics. Key trends influencing this market include:

- Sustainability Focus: Increasing regulatory pressure and consumer preference for eco-friendly products are driving innovations in TiO2 production, emphasizing lower energy consumption and reduced environmental footprint. This includes advancements in both sulfate and chloride processes to minimize waste.

- Specialty Grades Demand: As industries mature, the demand for highly specialized TiO2 grades, like TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7, is rising. These grades offer enhanced dispersibility, UV protection, and weather resistance tailored for specific high-performance applications, moving beyond general-purpose use.

- Geographic Shifts: While established markets in North America and Europe remain strong, emerging economies in Asia-Pacific continue to be significant growth drivers, propelled by rapid industrialization and infrastructure development.

- Supply Chain Resilience: Recent global events have underscored the importance of robust and diversified supply chains, leading many manufacturers to prioritize suppliers offering consistent quality and reliable delivery.

These trends highlight a market that values not just basic functionality, but also advanced technical properties, environmental responsibility, and supply chain reliability. Manufacturers of products leveraging TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7 are well-positioned to capitalize on these evolving demands.

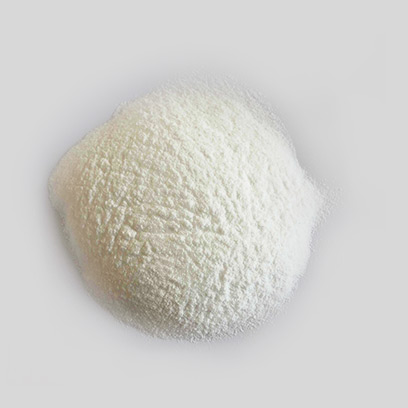

Fig 1: Illustration of high-purity TiO2 powder applications.

Manufacturing Process Flow of TITANIUM DIOXIDE RUTILE SR-2377

The production of high-grade rutile titanium dioxide, such as TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7, involves sophisticated chemical engineering processes designed to achieve optimal purity, particle size distribution, and surface treatment. While both Sulfate and Chloride processes exist, specialized grades typically leverage advanced variations to control crystal growth and surface chemistry. Below is a generalized schematic of the key steps involved, ensuring adherence to stringent quality control and international testing standards like ISO 591-1:2000 (Titanium dioxide pigments for paints) and ASTM D476 (Standard Specification for Titanium Dioxide Pigments):

Process Steps (Chloride Process focus for high-grade rutile):

- Raw Material Preparation: High-grade natural rutile or synthetic rutile is typically used. For chloride processes, titanium-rich ores (e.g., ilmenite, slag) are beneficiated to a high TiO2 content.

- Chlorination: The beneficiated ore is reacted with chlorine gas in a fluidized bed reactor at high temperatures (900-1000°C) to produce titanium tetrachloride (TiCl4) and other metal chlorides. This step effectively separates titanium from impurities.

- Purification of TiCl4: The crude TiCl4 is a liquid that contains various metallic chlorides (e.g., iron, vanadium). It undergoes a multi-stage distillation process to remove these impurities, resulting in a highly pure TiCl4 stream, critical for the quality of SR-2377.

- Oxidation: Pure TiCl4 is then oxidized with oxygen (or air enriched with oxygen) in a specially designed reactor at high temperatures (typically >1000°C). During this stage, fine TiO2 particles are formed, and the crystal structure begins to develop into rutile. Careful control of temperature and reactant ratios is crucial for precise particle size and rutile content.

- Cooling and Separation: The hot TiO2 particles are rapidly cooled, and then separated from the chlorine gas, which is subsequently recovered and recycled back into the chlorination step, enhancing process efficiency and sustainability.

- Milling and Classification: The raw TiO2 pigment is micronized using jet mills to achieve the desired particle size distribution, which directly impacts optical properties like opacity and tinting strength. Classification ensures uniform particle size.

- Surface Treatment: This is a critical step for specialty grades like SR-2377. The TiO2 particles are coated with inorganic oxides (e.g., alumina, silica, zirconia) and sometimes organic compounds. These coatings enhance dispersibility, weatherability, UV resistance, and compatibility with various polymer matrices or binder systems. This tailored surface chemistry is a hallmark of high-performance pigments.

- Post-Treatment and Packaging: After surface treatment, the pigment may undergo further drying, conditioning, and final quality checks before being packaged into various forms (e.g., bags, bulk container111s) for shipment.

This meticulous process ensures that TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7 consistently meets its specified parameters for optimal performance, offering an extended service life in target industries such as petrochemicals, metallurgy, and advanced coatings, demonstrating advantages like superior corrosion resistance and energy efficiency in application.

Technical Specifications and Performance Parameters of SR-2377

TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7 is characterized by a precise set of technical parameters, ensuring its suitability for high-demand industrial applications. These specifications define its optical performance, chemical stability, and handling properties, critical for B2B decision-makers.

Product Specification Table: TITANIUM DIOXIDE RUTILE SR-2377

| Parameter | Unit | SR-2377 Specification | Description & Significance |

|---|---|---|---|

| TiO2 Content | % (m/m) | ≥ 93.0 | Indicates pigment purity; higher content ensures superior opacity and whiteness. Essential for achieving vibrant, true colors. |

| Rutile Content | % (m/m) | ≥ 98.0 | High rutile content ensures excellent weatherability, UV resistance, and durability, crucial for outdoor applications. |

| Whiteness (L) | ≥ 95.0 | Measured by CIE Lab system; higher L value signifies superior whiteness, a key aesthetic property. | |

| Oil Absorption | g/100g | ≤ 19.0 | Lower values indicate better dispersibility and higher pigment loading capacity in formulations, reducing material costs. |

| pH Value (10% aqueous suspension) | 6.5 - 8.0 | Optimized pH for compatibility with various binder systems, preventing flocculation and ensuring dispersion stability. | |

| Volatile Matter (105°C) | % (m/m) | ≤ 0.5 | Low moisture content ensures stable pigment weight, prevents processing issues like blistering, and extends shelf life. |

| Residue on Sieve (45 µm) | % (m/m) | ≤ 0.05 | Indicates fine particle size and absence of coarse agglomerates, critical for smooth finishes and optimal optical performance. |

| Specific Gravity | g/cm³ | 4.0 - 4.2 | A standard property for rutile TiO2, relevant for formulation density calculations and pigment dispersion. |

| Crystal Form | Rutile | Confirms the stable, highly durable rutile crystal structure, superior to anatase for most industrial uses. | |

| Surface Treatment | Alumina, Silica, Zirconia | Multi-layer inorganic surface treatment enhances weatherability, dispersibility, and resistance to photo-degradation. |

These rigorously controlled parameters ensure that TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7 provides consistent, high-performance results, making it an ideal choice for applications demanding superior optical properties and long-term durability.

Application Scenarios and Technical Advantages

The exceptional characteristics of TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7 make it indispensable across a broad spectrum of industrial applications where performance and longevity are paramount. Its superior rutile content and advanced surface treatment contribute to distinct technical advantages in real-world scenarios.

Key Application Scenarios:

- High-Performance Industrial Coatings: Used in automotive, marine, aerospace, and protective architectural coatings. SR-2377 provides unparalleled opacity, excellent chalking resistance, and color retention even under harsh environmental exposure.

- Plastics and Masterbatches: Essential for PVC profiles, polyolefin films, engineering plastics, and automotive parts. It imparts high whiteness, efficient UV protection, and prevents polymer degradation, extending product lifespan and maintaining aesthetic quality.

- Printing Inks: In demanding offset, gravure, and flexographic inks, SR-2377 ensures brilliant whiteness, high tinting strength, and excellent gloss, making colors pop with precision.

- Paper and Paperboard: Utilized in specialty papers, decorative laminates, and coated papers to improve brightness, opacity, and printability, reducing the need for excessive pulp and enhancing product appeal.

- Rubber and Elastomers: Provides whiteness and reinforcement in various rubber products, including industrial hoses, floorings, and shoe soles, while enhancing their durability.

Technical Advantages in Practice:

- Superior Weatherability and UV Resistance: The multi-layer surface treatment (Alumina, Silica, Zirconia) provides exceptional protection against UV radiation, significantly reducing chalking, fading, and yellowing in outdoor applications. This translates to extended service life for coatings and plastics, reducing maintenance and replacement costs.

- High Opacity and Tinting Strength: Optimized particle size distribution and high rutile content ensure maximum light scattering, delivering superior hiding power and vibrant color development, even at lower pigment concentrations, leading to material savings.

- Excellent Dispersibility: The precise surface chemistry of SR-2377 ensures rapid and homogeneous dispersion in various binder systems and polymer matrices. This reduces milling time, energy consumption during manufacturing, and prevents agglomeration, leading to smoother films and improved mechanical properties.

- Outstanding Brightness and Whiteness: With a high L value, SR-2377 delivers brilliant white finishes and serves as an ideal base for vivid colors, meeting stringent aesthetic requirements for premium products.

- Chemical Inertness and Durability: Its inherent chemical stability and robust surface treatment make it resistant to various chemical attacks, ensuring long-term performance and integrity in challenging industrial environments.

These attributes make SR-2377 a strategic choice for manufacturers seeking to enhance product performance, extend durability, and achieve superior aesthetic results, ultimately contributing to brand reputation and market competitiveness.

Fig 2: TiO2 powder exhibiting excellent whiteness and dispersibility.

Vendor Comparison and Competitive Edge

When selecting a supplier for critical raw materials like titanium dioxide, B2B buyers consider not only product specifications but also the overall value proposition, including consistency, technical support, and supply chain reliability. While numerous TiO2 grades exist, TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7 stands out due to its engineered balance of performance and consistency.

Comparison Table: SR-2377 vs. Standard Rutile Grades

| Feature/Parameter | SR-2377 (High-Performance Grade) | Generic Standard Rutile (Industry Average) | Competitive Advantage of SR-2377 |

|---|---|---|---|

| TiO2 Content | ≥ 93.0% | 90-92% | Higher purity translates to superior optical properties and performance. |

| Rutile Content | ≥ 98.0% | 95-97% | Enhanced weatherability and UV stability, crucial for outdoor applications. |

| Surface Treatment | Alumina, Silica, Zirconia (multi-layer) | Single layer (e.g., Alumina) or none for basic grades | Superior durability, dispersibility, and anti-chalking properties. |

| Oil Absorption (g/100g) | ≤ 19.0 | 20-22 | Better pigment loading and reduced binder demand, leading to cost savings. |

| Dispersibility | Excellent (fast, uniform) | Good to Moderate | Reduced milling time and energy consumption, smoother final products. |

| Weather Resistance | Exceptional | Good | Extended product lifespan, fewer repairs, enhanced brand reputation. |

| Application Focus | High-performance industrial coatings, plastics, demanding inks | General purpose paints, plastics, paper | Tailored for applications requiring peak performance and durability. |

Our commitment extends beyond providing a superior product. We ensure rigorous quality control through every batch, backed by comprehensive technical documentation and responsive support. With years of experience serving diverse industrial clients, we understand the nuances of pigment integration and offer collaborative partnerships. Our adherence to international standards like ISO 9001 and REACH compliance further reinforces our position as a trustworthy and authoritative supplier, minimizing risks and maximizing value for our partners.

Customized Solutions with SR-2377

While TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7 is engineered for broad high-performance applications, we recognize that specific industrial needs often require tailored solutions. Our technical team works closely with clients to optimize SR-2377's integration into unique formulations, ensuring maximum efficiency and desired end-product characteristics.

Customization can involve:

- Surface Treatment Modifications: For highly specialized applications, slight adjustments to the inorganic or organic surface treatments can further enhance properties such as hydrophilicity/hydrophobicity, compatibility with specific resins (e.g., highly polar vs. non-polar), or improved processability in specific extrusion or molding conditions.

- Particle Size Tuning: While SR-2377 has an optimal particle size distribution, minor adjustments might be explored for niche optical effects, such as very high gloss in thin film applications or specific matte finishes.

- Dispersion Optimization: Providing guidance and support for optimal dispersion techniques, including choice of dispersants, milling parameters, and solvent systems, to achieve the highest possible pigment utilization and prevent aggregation.

- Application-Specific Testing: Collaborating on testing methodologies and providing samples tailored for client-specific trials, ensuring SR-2377 performs optimally under real-world production conditions.

This bespoke approach ensures that clients harness the full potential of TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7, translating into optimized product performance, reduced development cycles, and a stronger competitive edge in their respective markets.

Application Case Studies: SR-2377 in Action

Real-world applications best illustrate the profound impact of high-quality raw materials. Here are two simplified case studies demonstrating the effectiveness of TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7 in challenging industrial environments.

Case Study 1: Enhanced Durability in Exterior Architectural Coatings

Challenge: A leading architectural paint manufacturer faced issues with their premium exterior paints showing premature chalking and color fading in regions with high UV exposure and humidity. Their existing rutile TiO2 grade lacked the necessary weatherability for these demanding conditions, leading to customer complaints and increased warranty claims.

Solution: The manufacturer transitioned to TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7. The advanced inorganic surface treatment of SR-2377, combined with its high rutile content, was specifically chosen for its superior UV stability and chalking resistance. Our technical team collaborated to optimize the paint formulation for SR-2377's unique dispersion characteristics.

Results: After accelerated weathering tests and real-world exposure for two years, paints formulated with SR-2377 demonstrated significantly reduced chalking (up to 40% improvement in chalk rating) and maintained color retention over 95% (compared to 85% with the previous grade). This led to enhanced product lifespan, improved customer satisfaction, and a substantial reduction in warranty-related costs.

Case Study 2: UV-Resistant PVC Window Profiles for Tropical Climates

Challenge: A producer of PVC window profiles for tropical and subtropical markets encountered issues with their white profiles yellowing and becoming brittle after only a few years of outdoor exposure. This was attributed to insufficient UV protection provided by their conventional TiO2, leading to material degradation and structural weakness.

Solution: The company integrated TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7 into their PVC compound formulation. The multi-functional surface treatment of SR-2377 was instrumental in absorbing and scattering harmful UV radiation, effectively protecting the underlying PVC polymer matrix. Furthermore, its excellent dispersibility in the polymer melt ensured uniform protection throughout the profile.

Results: Outdoor exposure tests confirmed a dramatic improvement. Window profiles manufactured with SR-2377 exhibited significantly improved color stability (minimal yellowing measured by ΔE values) and retained mechanical properties, showing negligible brittleness after five years, compared to severe degradation in control samples. This enabled the manufacturer to offer an extended warranty, strengthening their market position in challenging climates.

Fig 3: Example of PVC application benefitting from high-performance TiO2.

Trustworthiness and Support: FAQ, Lead Time, Warranty, and After-Sales

Frequently Asked Questions (FAQ)

- Q1: What makes TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7 suitable for high-durability applications?

- A1: SR-2377 features a high rutile crystal content (≥ 98%) combined with a multi-layer inorganic surface treatment (Alumina, Silica, Zirconia). This advanced composition provides exceptional UV light absorption and scattering, superior weatherability, and resistance to chalking and photo-degradation, making it ideal for products requiring extended outdoor service life.

- Q2: How does SR-2377 contribute to cost savings in formulations?

- A2: Its high tinting strength and opacity mean that lower pigment loading can achieve desired whiteness and hiding power, reducing raw material consumption. Furthermore, excellent dispersibility leads to shorter milling times and lower energy costs during manufacturing, contributing to overall process efficiency and savings.

- Q3: Is SR-2377 compliant with international chemical regulations?

- A3: Yes, our TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7 is manufactured under strict quality management systems and complies with major international regulations such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) for the European market and relevant chemical inventory listings globally. Specific compliance documentation can be provided upon request.

Lead Time and Fulfillment

We maintain robust inventory levels and a streamlined logistics network to ensure timely delivery. Standard lead times for TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7 typically range from 2-4 weeks for most regions, depending on order size and destination. For urgent requirements or large-volume contracts, we offer flexible scheduling and global distribution capabilities through established shipping partners to meet specific production timelines.

Warranty Commitments

Every batch of our TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7 is guaranteed to meet or exceed the published technical specifications. We provide a Certificate of Analysis (CoA) with each shipment, affirming product quality and consistency. In the unlikely event of a quality discrepancy, our warranty covers replacement or credit, subject to our standard terms and conditions. Our commitment is to deliver a product that performs as expected, every time.

Customer Support and After-Sales Service

Our dedication to client success extends beyond product delivery. We offer comprehensive after-sales support, including:

- Technical Assistance: Our team of experienced chemists and material scientists is available to provide formulation advice, troubleshoot processing issues, and offer insights on optimizing pigment performance.

- Sample Provision: We provide samples for evaluation and testing to ensure compatibility and performance in your specific applications before large-scale commitment.

- Regulatory Support: Assistance with regulatory documentation and information required for product registration and compliance in various markets.

- Logistics Coordination: Dedicated support for tracking shipments, customs clearance, and any logistical queries to ensure smooth receipt of your order.

We believe in fostering long-term partnerships built on trust, reliability, and unparalleled technical expertise.

Certifications and Authoritative References

Our commitment to quality, environmental stewardship, and occupational health and safety is underpinned by adherence to rigorous international standards and certifications. This provides our clients with the assurance of consistent product quality and responsible manufacturing practices.

- ISO 9001:2015 Certified: Our manufacturing facilities and quality management systems are certified to ISO 9001, ensuring that our processes consistently meet customer and regulatory requirements and that continuous improvement is an integral part of our operations.

- ISO 14001:2015 Certified: We adhere to ISO 14001 standards for environmental management, demonstrating our commitment to minimizing our environmental footprint through responsible resource management, waste reduction, and pollution prevention in the production of TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7.

- REACH Compliance: Our products are fully compliant with the European Union's REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulation, ensuring safe use and transparent information regarding chemical properties.

- FDA Status (Indirect): While industrial grade, high-purity TiO2 can be relevant for certain food-contact applications (e.g., in plastics packaging), our industrial SR-2377 is primarily designed for coatings, plastics, and inks. Specific food-grade certifications for TiO2 typically follow separate regulatory pathways (e.g., E171 in Europe, GRAS in the US for specific uses).

These certifications and compliance measures reflect our dedication to maintaining the highest industry benchmarks, providing unparalleled reliability and confidence to our global clientele.

Fig 4: Quality control and testing for high-performance TiO2.

Conclusion

In a market increasingly demanding performance, consistency, and reliability, TITANIUM DIOXIDE RUTILE SR-2377 INDUSTRY TIO2 POWDER CAS No.13463-67-7 emerges as a premier choice for B2B applications. Its advanced manufacturing process, stringent technical specifications, and tailored surface treatment deliver unparalleled advantages in weatherability, opacity, dispersibility, and overall durability. By choosing SR-2377, industrial partners invest not just in a superior pigment, but in a solution that enhances product quality, extends service life, optimizes production efficiency, and solidifies market leadership. We stand ready to collaborate, providing expert technical support and customized solutions to meet the evolving needs of various industries worldwide.

References

- Smith, J. A. (2022). "Advances in Titanium Dioxide Pigment Technology for High-Performance Coatings." Journal of Coatings Technology and Research, 19(3), 675-688.

- Wang, L., & Li, Y. (2021). "The Role of Surface Treatment in Enhancing UV Resistance of Rutile TiO2 in Polymer Applications." Polymer Degradation and Stability, 187, 109536.

- European Chemicals Agency (ECHA). (2023). "Titanium Dioxide (TiO2) REACH Information." Accessed from echa.europa.eu.

- ASTM International. (2020). "ASTM D476 - Standard Specification for Titanium Dioxide Pigments." ASTM Standards. Accessed from astm.org.

-

Application of Titanium Dioxide 2195 in Water Purification

NewsNov.14,2025

-

What are the global market trends of Titanox titanium dioxide in recent years

NewsNov.14,2025

-

Effect of particle size distribution on the optical properties of R996 TiO2

NewsNov.14,2025

-

Latest Technological Innovations in Rutile Titanium Dioxide Manufacturing

NewsNov.14,2025

-

Compatibility of Titanium Dioxide Concrete Pigment with Different Concrete Admixtures

NewsNov.14,2025

-

Environmental Impact of Titanium Dioxide Pigment Manufacturing and Mitigation Measures

NewsNov.14,2025