Oct . 24, 2025 00:35 Back to list

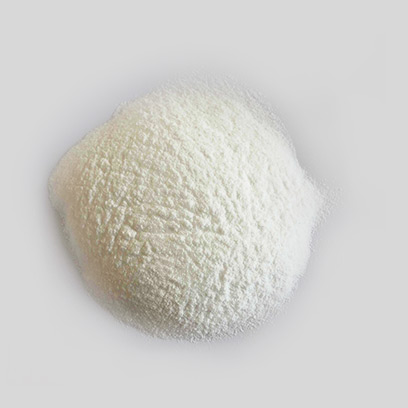

ti02 titanium dioxide | High-Purity, UV-Stable, R902/6618

Ti02 Titanium Dioxide is a key solution in the manufacturing industry, specifically within Chemical raw material and chemical product manufacturing industry and Pigment manufacturing. This article explores how Hebei Caiqing New Material Technology Co., LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Ti02 Titanium Dioxide Overview

- Benefits & Use Cases of Ti02 Titanium Dioxide in Pigment manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Ti02 Titanium Dioxide from Hebei Caiqing New Material Technology Co., LTD

Ti02 Titanium Dioxide Overview

Ti02 Titanium Dioxide (TiO2) is the industry’s benchmark white pigment, valued for its exceptional opacity, brightness, and UV resistance. In pigment manufacturing, its high refractive index enables superior hiding power across coatings, plastics, inks, and paper. Hebei Caiqing New Material Technology Co., LTD supplies rutile-grade TiO2 engineered for consistent dispersion, gloss retention, and weatherability—key performance factors for B2B buyers seeking dependable, repeatable quality at scale. The company’s SR-2377 rutile grade aligns with market-proven standards seen alongside grades such as R902 titanium dioxide and 6618 titanium dioxide, providing robust film integrity and a clean, neutral to blue undertone that formulators prefer over buff titanium dioxide shades when targeting maximum whiteness.

Technically, optimized particle size distribution and surface treatment deliver low oil absorption and fast wet-in, which shortens mill time and reduces dispersant demand. This profile supports high-solids systems and low-VOC targets without sacrificing tint strength. For specialized applications where texture modifiers or extenders are used, TiO2 integrates well with talc titanium dioxide systems to balance cost and rheology. Hebei Caiqing’s quality controls ensure batch-to-batch stability, supporting global customers that purchase titanium dioxide bulk for continuous production. Whether you specify pure titanium dioxide for critical color or reference trade names (including “arti titanium dioxide” in some catalogs), Hebei Caiqing provides technical support and documentation to help you meet stringent manufacturing specs.

Benefits & Use Cases of Ti02 Titanium Dioxide in Pigment manufacturing

In pigment manufacturing, Ti02 Titanium Dioxide is the workhorse pigment for high-opacity systems: architectural and industrial coatings, powder coatings, automotive OEM/refinish, PVC pipes and profiles, masterbatch for film and injection molding, and high-speed publication inks. Hebei Caiqing’s rutile TiO2 is engineered for strong hiding power, neutral undertone, and photochemical stability, enabling thinner films with the same coverage—an immediate cost and sustainability win. Formulators report easier dispersion and lower grind energy versus commodity options, which helps standardize gloss and color across multiple production lines and geographies.

Competitive advantages include reliable whiteness index, excellent chalking resistance in exterior coatings, and heat stability for demanding polymer processing. When compared with commonly referenced benchmarks like r902 titanium dioxide or 6618 titanium dioxide, SR-2377 focuses on consistent particle treatment for clean color and long-term durability. For cost-optimized systems, TiO2 can be co-formulated with functional fillers (e.g., talc titanium dioxide blends) while maintaining opacity targets. Hebei Caiqing New Material Technology Co., LTD backs these use cases with application testing, technical data packs, and scale-up guidance—critical for B2B decision makers consolidating suppliers or planning multi-plant standardization. The result is a dependable pigment platform suitable for both premium and value-tier formulations.

Cost, Maintenance & User Experience

For B2B buyers, total cost of ownership extends beyond the titanium dioxide cost per metric ton. Hebei Caiqing’s Ti02 Titanium Dioxide is designed to reduce mill time, dispersant use, and rework—yielding tangible production savings. Its high hiding power supports lower pigment loading or thinner dry film thickness, which compounds savings in resin and solvent. Bulk procurement programs (titanium dioxide bulk) and predictable lead times help stabilize inventory and mitigate market volatility. Users also value the reduced shade drift and improved color consistency, which decrease off-spec batches and QA overhead.

From a safety standpoint, publicly available toxicology data typically cite high oral LD50 values (ld50 titanium dioxide in the “practically non-toxic” range for many animal models). As with any industrial powder, follow the SDS and local regulations, ensure dust control, and store in dry, sealed packaging to maintain flow and avoid contamination. Customer feedback from coatings and plastics processors indicates strong gloss development, smooth film formation, and stable whiteness over time. These user experiences, combined with Hebei Caiqing’s responsive technical support and reliable logistics, translate into improved ROI compared with lower-consistency commodity alternatives and reduce the hidden costs of process variability.

Sustainability & Market Trends in manufacturing

Global pigment markets are shaped by sustainability targets, regulatory alignment (REACH, TSCA, RoHS), and value-chain decarbonization. Formulators are cutting VOCs, extending coating lifetimes, and minimizing film thickness—all areas where Ti02 Titanium Dioxide’s opacity and UV resistance deliver measurable benefits. Durable, weatherable TiO2 grades reduce repaints and material consumption across asset lifecycles, while efficient dispersion lowers energy during manufacturing. Market indicators show continued demand for high-performance rutile pigments in industrial coatings, powder coatings, plastics masterbatch, and inkjet/digital inks as producers seek reliable whiteness and brand consistency.

Hebei Caiqing New Material Technology Co., LTD positions its TiO2 portfolio to support these trends through strict raw material qualification, process control for consistent particle treatment, and packaging designed for safe handling and recyclability. The company offers documentation to assist with compliance audits and can advise on formulations targeting low-VOC or low-odor specifications. Whether you are benchmarking pure titanium dioxide performance, evaluating alternatives listed as “arti titanium dioxide,” or rationalizing suppliers for global plants, Hebei Caiqing’s forward-thinking approach helps balance performance, regulatory needs, and cost stability in dynamic markets.

Conclusion on Ti02 Titanium Dioxide from Hebei Caiqing New Material Technology Co., LTD

For pigment manufacturing in the chemical raw material sector, Ti02 Titanium Dioxide remains indispensable for opacity, brightness, and durability. Hebei Caiqing New Material Technology Co., LTD delivers rutile-grade performance that streamlines dispersion, stabilizes color, and optimizes cost-in-use—ideal for coatings, plastics, and inks. With consistent quality, technical support, and dependable bulk supply, the company is a trusted partner for B2B decision makers seeking scalable value.

- Contact us: email: sales01@cqtitaniumdioxide.com

- Visit our website: https://www.cqtitaniumdioxide.com

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025