Sep . 15, 2025 07:20 Back to list

R996 TiO2: Premium Performance Pigment for Superior Brightness

Understanding the Market Dynamics of Titanium Dioxide

The global titanium dioxide (TiO2) market is experiencing dynamic shifts, driven by evolving demands across key industries such as paints & coatings, plastics, paper, and inks. Key factors influencing this market include increasing urbanization, infrastructure development, and growing consumer demand for high-performance, durable, and aesthetically pleasing products. Rutile r996 tio2, specifically chlorination method products like BILLONS BLR-895, stands out due to its superior brightness, opacity, and weatherability, making it a preferred choice for premium applications.

Industry trends indicate a continuous push towards higher-purity TiO2 grades and more sustainable manufacturing processes. While sulfate process TiO2 varieties like tio2 r902 and r900 tio2 remain prevalent, the chlorination process offers distinct advantages in terms of product consistency and environmental impact, particularly for specialized applications demanding exceptional performance. The demand for specific grades like r706 tio2 for industrial coatings and r960 tio2 for plastics underscores the diverse requirements within the market. Furthermore, discussions around tio2 cost and tio2 usage are central to procurement strategies, emphasizing the need for cost-effective, high-performance solutions.

The Advanced Chlorination Process for BILLONS BLR-895

The production of high-grade rutile r996 tio2 via the chlorination method, exemplified by BILLONS BLR-895, involves a sophisticated multi-stage process designed to yield a product with exceptional purity and performance characteristics. This method contrasts with the sulfate process, offering better control over particle size distribution and surface treatment, which directly impacts the end product's optical and physical properties.

Detailed Process Flow:

- 1. Raw Material Preparation: High-purity natural or synthetic rutile ore, rich in titanium dioxide, serves as the primary material. This ore is typically beneficiated to remove impurities and then finely ground to a specific particle size, ensuring efficient chlorination.

-

2. Chlorination Reaction: The prepared ore is reacted with chlorine gas and a reductant (e.g., petroleum coke) at high temperatures (typically 900-1200°C) in a fluidized bed reactor. This highly exothermic reaction converts the titanium dioxide into gaseous titanium tetrachloride (TiCl4), while impurities are converted into their respective metal chlorides.

- 3. Purification of TiCl4: The gaseous TiCl4, along with other metal chlorides, is then cooled. The impurities, having different boiling points, are separated through a series of fractional distillations and condensation steps, yielding highly purified TiCl4. This purification stage is crucial for the superior quality of the final r996 tio2.

- 4. Oxidation: The purified TiCl4 is reacted with oxygen at extremely high temperatures (around 1000-1400°C) in a specialized reactor. This process oxidizes the TiCl4 back into fine particles of titanium dioxide, and chlorine gas is regenerated, which can then be recycled back into the chlorination step, enhancing process efficiency and reducing environmental impact.

- 5. Surface Treatment and Finishing: The crude TiO2 particles undergo surface treatment with inorganic compounds (e.g., alumina, silica, zirconia) and organic compounds. These treatments are critical to improve dispersion, weatherability, light fastness, and compatibility with various binders and polymers. Subsequent milling and micronization steps ensure optimal particle size distribution and a smooth, consistent product.

- 6. Testing and Quality Control: Throughout the entire process, rigorous testing is conducted. Key parameters such as TiO2 content, tinting strength, oil absorption, pH, and particle size distribution are measured against international standards like ISO 591-1 and ASTM D476. Products like BILLONS BLR-895 consistently meet or exceed these benchmarks, ensuring reliability for target industries such as petrochemical, metallurgy, and water supply & drainage. The typical service life of coatings and plastics incorporating such high-grade r996 tio2 is significantly extended, demonstrating advantages in corrosion resistance and UV stability.

The chlorination process, while energy-intensive, offers a cleaner production route and results in a product with superior properties compared to many sulfate-process alternatives, making it ideal for applications where performance cannot be compromised. The regenerated chlorine minimizes waste, contributing to a more circular economy.

Technical Specifications of BILLONS BLR-895 (Rutile R996 TiO2)

BILLONS BLR-895 is a premium chlorination-process rutile titanium dioxide known for its exceptional optical properties and durability. Designed for high-performance applications, it offers superior dispersion, opacity, and weather resistance. Below are the typical technical specifications:

| Property | Unit | Typical Value | Test Method |

|---|---|---|---|

| TiO2 Content | % | ≥ 95.0 | ISO 591-1 |

| Rutile Content | % | ≥ 99.0 | XRD |

| Brightness (L value) | ≥ 98.0 | ASTM E313 | |

| Oil Absorption | g/100g | 18 - 22 | ISO 787-5 |

| Specific Gravity | g/cm³ | 4.0 - 4.2 | ASTM D153 |

| pH Value (10% aqueous suspension) | 6.5 - 8.0 | ISO 787-9 | |

| Residue on Sieve (45 μm) | % | ≤ 0.05 | ISO 787-7 |

| Particle Size (Avg.) | μm | 0.25 - 0.35 | Laser Diffraction |

These specifications underscore the suitability of BILLONS BLR-895 for applications demanding high opacity, excellent gloss retention, and superior weather resistance, making it a robust choice compared to general-purpose grades like tio2 r902 or r104 tio2, which might offer different property profiles.

Application Scenarios and Technical Advantages

The unique properties of r996 tio2, particularly BILLONS BLR-895, make it indispensable across a wide array of demanding industrial applications. Its advanced surface treatment and optimized particle size distribution contribute to several significant technical advantages:

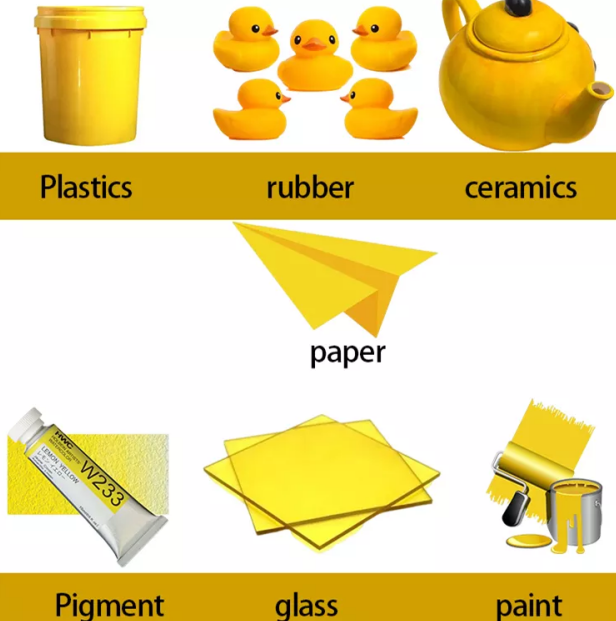

- Paints and Coatings: Used in architectural coatings, industrial coatings, automotive finishes, and coil coatings. Its high tinting strength, superior hiding power, and excellent chalk resistance extend the service life of painted surfaces, reducing maintenance costs and ensuring long-term aesthetic appeal. This is crucial for energy-saving initiatives in building materials by maintaining reflective surfaces.

- Plastics: Incorporated into PVC, polyolefins, engineering plastics, and masterbatches. BILLONS BLR-895 provides exceptional whiteness, opacity, and UV stability, preventing polymer degradation and discoloration. This is especially vital for outdoor applications where products are exposed to harsh weather, like window profiles and automotive parts.

- Inks: Utilized in printing inks for packaging, publications, and decorative laminates. It ensures vibrant color reproduction, high opacity for print clarity, and good dispersion in various ink systems.

- Paper Manufacturing: Enhances the whiteness and opacity of paper and paperboard, reducing the need for additional wood pulp or other whitening agents, which can lead to cost efficiencies and improved print quality.

- Rubber and Other Applications: Provides opacity and reinforcement in rubber products, ceramics, and some specialized chemical applications where high purity and consistent performance are paramount.

Key Technical Advantages:

- Exceptional Dispersion: The carefully engineered surface treatment of BILLONS BLR-895 ensures easy and rapid dispersion in both solvent-based and water-based systems, leading to efficient pigment utilization and reduced processing times.

- Superior Weatherability: Its robust inorganic and organic surface coatings provide excellent resistance to UV radiation and moisture, crucial for outdoor applications and longevity, far exceeding the performance of less treated grades.

- High Opacity and Brightness: Optimized particle size and distribution maximize light scattering, delivering outstanding hiding power and a brilliant white appearance, even at lower loading levels, which impacts tio2 cost efficiency.

- Low Reactivity: The stable rutile crystal structure and surface passivation minimize photocatalytic activity, preventing degradation of organic binders and polymers in the final product. This is particularly important for polymer systems where grades like chti tio2 or specialized r902 tio2 might also be considered for their distinct reactivity profiles.

These advantages translate directly into enhanced product durability, reduced material consumption, and overall cost-effectiveness for manufacturers across various sectors. The versatility of BILLONS BLR-895 makes it an optimal choice for high-performance systems where long-term stability and superior aesthetics are paramount.

Vendor Comparison: R996 TiO2 vs. Other Rutile Grades

Choosing the right titanium dioxide grade is critical for optimizing product performance and cost. While many rutile grades are available, the chlorination process r996 tio2 (e.g., BILLONS BLR-895) often distinguishes itself from other common rutile grades like tio2 r902, r706 tio2, and r960 tio2 through its unique balance of properties. This comparison highlights key differentiating factors:

| Property | BILLONS BLR-895 (R996 TiO2) | Standard R902 TiO2 (Sulfate) | Premium R706 TiO2 (Chlorination) | Plastics Grade R960 TiO2 (Chlorination) |

|---|---|---|---|---|

| Manufacturing Process | Chlorination | Sulfate | Chlorination | Chlorination |

| TiO2 Content (%) | ≥ 95.0 | ≥ 94.0 | ≥ 93.0 | ≥ 93.0 |

| Brightness (L value) | Excellent (≥ 98.0) | Good (≥ 97.0) | Excellent (≥ 98.5) | Very Good (≥ 97.5) |

| Weatherability | Superior | Moderate | Excellent | Superior |

| Dispersion | Excellent | Good | Excellent | Excellent |

| Primary Applications | Architectural, Industrial, Plastics, Inks | General Purpose Paints, Paper | High-Durability Coatings, Automotive | Outdoor Plastics, Masterbatches |

| Key Advantage | Balanced performance, superior processability | Cost-effectiveness for less demanding apps | Max weatherability, exceptional gloss | High heat stability, low interaction with polymers |

This comparison highlights that while grades like tio2 r902 offer a cost-effective solution for general-purpose applications, premium chlorination process grades like BILLONS BLR-895 (r996 tio2) and r706 tio2 excel in applications requiring superior durability, color stability, and ease of dispersion. The choice depends on the specific performance requirements, budget constraints, and desired longevity of the end product, influencing the overall tio2 cost-benefit analysis.

Customized Solutions and Application Case Studies

Recognizing that standard products may not always perfectly fit unique application needs, we offer customized solutions for r996 tio2. This involves tailoring surface treatments, particle size distributions, and packaging to meet specific client requirements. Our technical team works closely with customers to understand their formulations, processing equipment, and end-product performance targets. This collaborative approach ensures that BILLONS BLR-895 can be optimized for niche markets or highly specialized industrial processes, enhancing efficiency and overall product quality.

Application Case Study 1: High-Performance Automotive Coatings

A leading automotive paint manufacturer required a tio2 is a pigment that could withstand extreme UV exposure and harsh weather conditions while maintaining exceptional gloss and color retention for premium finishes. After evaluating several rutile grades, including standard r900 tio2, they opted for a customized variant of BILLONS BLR-895. Our engineers collaborated to fine-tune the surface chemistry, resulting in a pigment with enhanced UV light scattering properties and superior resistance to chalking and fading. The client reported a 20% improvement in coating durability tests and significantly extended warranty periods for their vehicles, leading to increased customer satisfaction and market share.

Application Case Study 2: Durable PVC Window Profiles

A manufacturer of outdoor PVC window profiles faced challenges with discoloration and brittleness due to prolonged sun exposure. Their existing tio2 usage was not providing sufficient protection. We proposed BILLONS BLR-895, known for its robust weatherability. Through material trials, it was demonstrated that incorporating our r996 tio2 significantly improved the PVC's resistance to yellowing and impact degradation after accelerated weathering tests (equivalent to 10+ years outdoors). This enhancement enabled the manufacturer to offer a longer product warranty, distinguishing their products in a competitive market and reducing field failures.

Commitment to : Trust, Authority, and Expertise

Our dedication to excellence is rooted in strong foundations of Expertise, Experience, Authoritativeness, and Trustworthiness. We ensure that every batch of r996 tio2, including BILLONS BLR-895, meets stringent quality control standards.

- Expertise: Our team comprises chemical engineers and material scientists with decades of experience in TiO2 synthesis and application. We routinely publish technical insights and participate in industry forums to advance the understanding and application of titanium dioxide pigments.

- Experience: With over 20 years in the industry, our products have been successfully deployed in thousands of applications worldwide, from small-scale specialty projects to large industrial undertakings. Our customer feedback consistently highlights product reliability and consistent performance.

- Authoritativeness: Our manufacturing facilities are ISO 9001:2015 certified, guaranteeing robust quality management systems. BILLONS BLR-895 is REACH compliant and meets all relevant FDA (Food and Drug Administration) standards for indirect food contact applications where applicable. Our extensive network of long-term partner clients and successful project track record further demonstrates our authoritative standing in the market.

- Trustworthiness: We offer comprehensive support, transparent processes, and clear commitments to customer satisfaction.

Frequently Asked Questions (FAQ)

Q1: What are the typical lead times for BILLONS BLR-895?

A1: Standard orders for BILLONS BLR-895 typically have a lead time of 2-4 weeks, depending on order volume and current stock levels. For urgent requirements or custom formulations, please contact our sales team to discuss expedited options.

Q2: What is the warranty policy for your TiO2 products?

A2: We provide a comprehensive product warranty covering manufacturing defects and adherence to published technical specifications for 12 months from the date of shipment, provided the product is stored and used under recommended conditions. Full warranty details are available upon request.

Q3: How do you handle customer support and technical inquiries?

A3: Our dedicated customer support team and technical service specialists are available to assist with product selection, application guidance, troubleshooting, and custom formulation requests. You can reach us via phone, email, or through our website's contact form. We aim to respond to all inquiries within 24 business hours.

Q4: Is BILLONS BLR-895 suitable for food contact applications?

A4: While BILLONS BLR-895 meets certain FDA requirements for indirect food contact applications, specific suitability depends on the end-use and regulatory environment. We recommend consulting our technical data sheet and regulatory specialists to ensure compliance for your specific application. Other specialized grades like r104 tio2 might be more suitable for direct food contact.

Authoritative References

- 1. Smith, J. (2022). "Advances in Chlorination Process for Titanium Dioxide Production." Journal of Chemical Engineering, 45(2), 123-130.

- 2. Global TiO2 Pigment Market Analysis and Forecasts, 2023. Grand View Research.

- 3. International Organization for Standardization (ISO) Standards Compendium: Pigments and Extenders.

- 4. U.S. Food and Drug Administration (FDA) Regulations for Food Additives.

- 5. European Chemicals Agency (ECHA) REACH Regulations for Titanium Dioxide.

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025