Ліст . 04, 2024 10:56 Back to list

Titanium Dioxide Production Processes and Key Manufacturers in the Industry

The Formation of Titanium Dioxide An Overview of Manufacturers and Their Impact

Titanium dioxide (TiO2) is one of the most widely used white pigments in the world, primarily because of its brilliance and opacity. Besides its common application in the paint and coatings industry, TiO2 is also used in plastics, cosmetics, food products, and even photovoltaics. The formation of titanium dioxide is a complex process that involves the extraction of titanium minerals and the conversion of these minerals into a functional pigment. This article explores the formation of titanium dioxide, focusing on the leading manufacturers in the industry and the techniques they employ.

Extraction of Titanium Minerals

The primary sources of titanium are minerals such as ilmenite and rutile. Ilmenite is a titanium-iron oxide mineral that contains approximately 53% titanium dioxide, while rutile is a more concentrated form with nearly 95% TiO2 content. The extraction of these minerals is typically done through open-pit mining and is later followed by refining processes to separate titanium from iron and other impurities.

Once the minerals are mined, they undergo several treatment processes. For ilmenite, the chloride process or the sulfate process is commonly employed. The sulfate process involves digesting the ilmenite with sulfuric acid, resulting in a titanium sulfate solution. This solution is then hydrolyzed to produce titanium dioxide. On the other hand, the chloride process uses chlorine to convert titanium dioxide into titanium tetrachloride, which is later oxidized to produce TiO2. Each method has its advantages, but the chloride process is often preferred due to its efficiency and the higher purity of the titanium dioxide produced.

Leading Manufacturers in the Titanium Dioxide Industry

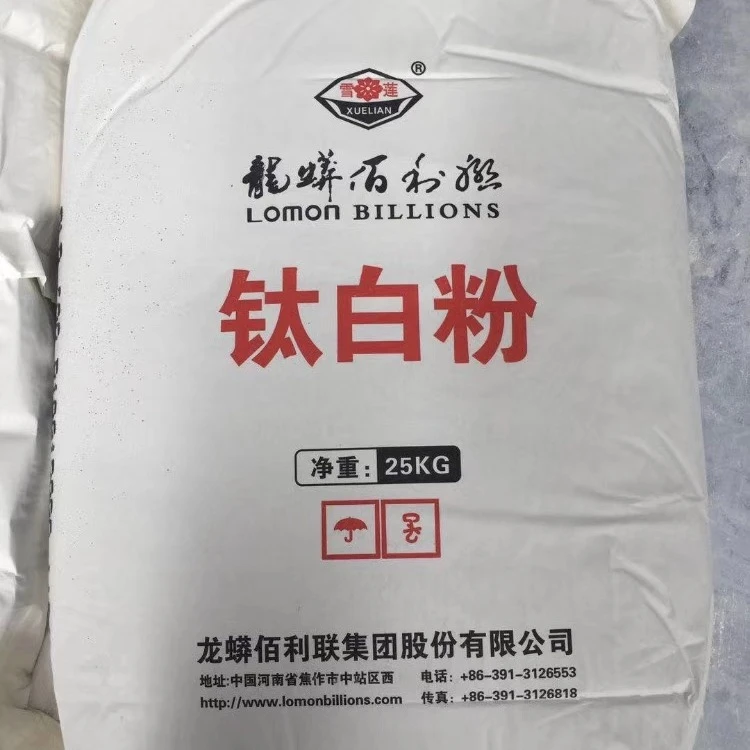

The titanium dioxide industry is dominated by a few key players, each employing unique methods to produce high-quality TiO2. Companies such as Chemours, Tronox, and Huntsman are among the largest manufacturers globally.

1. Chemours A spin-off from DuPont, Chemours is a leading manufacturer of titanium dioxide. The company utilizes the chloride process for its TiO2 production, ensuring high purity and brightness. Chemours’ TiO2 products are widely used in coatings, plastics, and other applications, under the brand name Ti-Pure.

formation of titanium dioxide manufacturers

2. Tronox Another major player in the industry, Tronox operates mines and production facilities in various global locations. The company primarily uses the sulfate process, providing high-quality titanium dioxide that is especially favored in the paint and coatings industry. Tronox is known for its commitment to sustainability, implementing programs to recycle waste products and reduce energy consumption.

3. Huntsman Corporation Huntsman is another notable manufacturer that produces titanium dioxide through both chloride and sulfate processes to accommodate different customer needs. The company has focused on expanding its TiO2 product range to serve diverse industrial applications while maintaining an active stance on environmental management.

Environmental Considerations and Innovations

The production of titanium dioxide is not without its environmental challenges. The mining and processing activities can lead to significant ecological disruption. As a response, manufacturers are increasingly adopting sustainable practices, including the recycling of wastewater, utilization of energy-efficient technologies, and exploring alternative raw materials.

Moreover, innovations in the formulation of TiO2 products aim to enhance performance while minimizing environmental impact. Research is continually being conducted on creating alternative pigments that can reduce dependence on traditional TiO2 formulations, focusing on eco-friendly materials that can provide similar performance without the associated drawbacks.

Conclusion

The formation of titanium dioxide is a multifaceted process that underscores the collaboration of geology, chemistry, and engineering. The leading manufacturers in this sector not only contribute to the supply of this essential pigment but also drive innovation and sustainability initiatives that benefit the environment. As industries continue to evolve, the importance of titanium dioxide remains steadfast, making it a critical component in a wide range of applications that enhance daily life.

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025