снеж . 10, 2024 10:05 Back to list

Methods for Analyzing Barium Content in Titanium Dioxide Products from Various Suppliers

Determination of Barium as TiO2 Suppliers and Their Role in Material Quality

Barium, a chemical element with the symbol Ba, plays a critical role in various industries, particularly when it comes to the production and application of titanium dioxide (TiO2). As TiO2 is one of the most widely used white pigments and is essential in applications ranging from paints and coatings to plastics and cosmetics, understanding the relationship between barium and TiO2, as well as the suppliers involved in this sector, is paramount for manufacturers and researchers alike.

The Importance of Barium in TiO2 Production

Barium compounds are pivotal in enhancing the properties of TiO2 pigments. Barium sulfate (BaSO4), for instance, is frequently used as an opacifying agent that improves the whiteness and coverage of TiO2-based formulations. The presence of barium in TiO2 can affect the particle size and dispersion characteristics, ultimately influencing the pigment's performance in various applications. This interaction is critical because the efficiency and aesthetic qualities of the final product rely heavily on these properties.

Challenges in Sourcing Barium for TiO2 Production

Finding reliable suppliers of barium compounds can pose challenges due to varying quality standards and the need for consistent production processes. Impurities and variable compositions can significantly impact the effectiveness of barium in TiO2 formulations. Therefore, manufacturers must conduct thorough assessments of their suppliers to ensure they meet specific criteria in terms of purity, availability, and compliance with environmental regulations.

Quality control is a key aspect in the sourcing of barium. Suppliers that adhere to ISO certifications and provide detailed documentation regarding the composition of their products tend to be more reliable. Manufacturers must establish strong relationships with their suppliers, ensuring that they can trust the consistency of the materials being provided. Regular audits, quality assessments, and third-party testing are essential practices to ensure that the barium sourced is of the highest quality for TiO2 applications.

determination of barium as tio2 suppliers

Leading Suppliers in the Market

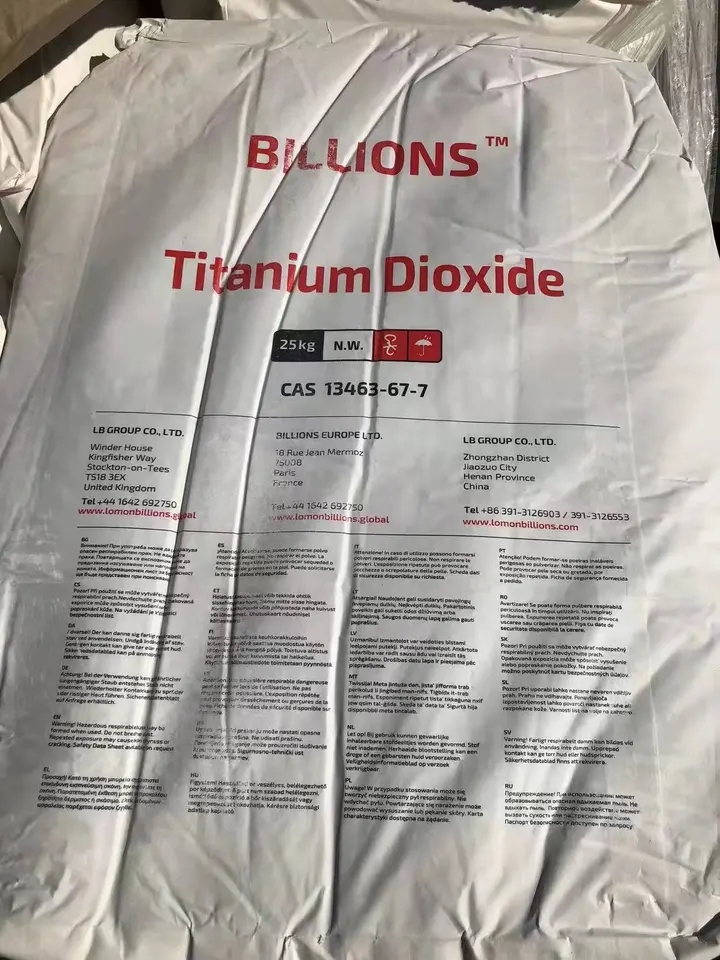

Several leading suppliers are recognized in the industry for their contributions to the supply of barium compounds for TiO2 production. Companies such as Barium & Chemicals, Inc., Albemarle Corporation, and Solvay Group are known for their commitment to quality and innovation in chemistry. These companies have established reputations for providing consistent, high-quality barium salts that meet the stringent requirements of their customers.

In addition, these suppliers often invest in research and development, striving to improve the efficacy of their products, which includes investigating new formulations or methods of processing that can lead to enhanced performance in TiO2. This focus on continuous improvement not only benefits the suppliers but also enables their customers to produce pigments that are more effective and environmentally friendly.

The Future of Barium in TiO2 Applications

As the demand for high-quality TiO2 continues to grow, particularly with the increasing applications in eco-friendly and sustainable products, the importance of barium compounds is expected to remain significant. Innovations in the field of material science may lead to new ways to integrate barium into TiO2 formulations, thereby enhancing pigment properties while also focusing on sustainability and reduced environmental impact.

Moreover, the rising emphasis on regulatory compliance presents both challenges and opportunities for suppliers of barium. Companies that proactively adapt to these changes by developing greener processes and sustainable sourcing practices will likely secure a competitive advantage in the future marketplace.

In conclusion, the determination of barium's role in TiO2 production is crucial for manufacturers seeking to optimize the quality of their products. Engaging with reliable suppliers and maintaining rigorous quality control measures are vital steps in ensuring superior performance in various applications of titanium dioxide. As trends evolve and new demands arise, the partnership between suppliers and manufacturers will be essential in driving innovation and sustaining quality in the TiO2 market.

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025

-

High Quality Titanium Dioxide Used in Rubber – Trusted Supplier & Factory Price

NewsJul.08,2025

-

High Purity Barium Sulfate Particle Size - Wholesale Manufacturer from China

NewsJul.07,2025

-

Premium Titanium Dioxide Lomon R-996 Supplier – Quality & Wholesale Price from China

NewsJul.07,2025

-

Top Titanium Manufacturers in China - Quality Titanium Dioxide Supplier & Production Line Solutions

NewsJul.06,2025

-

OEM Titanium White Supplier & Factory – High Purity, Consistent Quality for Industrial Use

NewsJul.06,2025