ديسمبر . 26, 2024 17:07 Back to list

Titanium Dioxide R996 Production Techniques and Quality Standards Overview

The Significance of Titanium Dioxide R996 in Industrial Applications

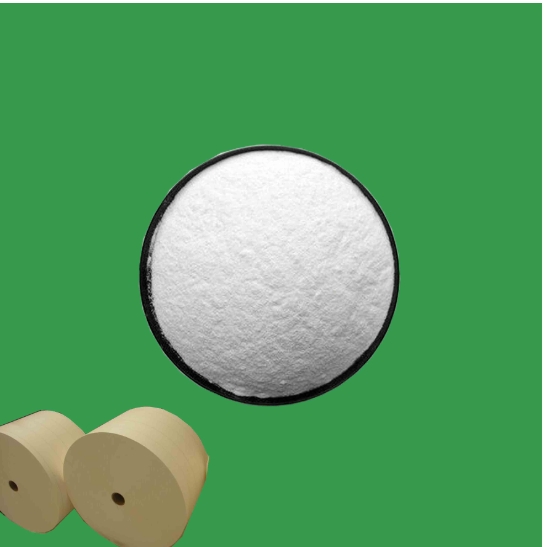

Titanium dioxide (TiO2), particularly the grade R996, has gained immense popularity in various industrial applications due to its exceptional properties. Often referred to as a versatile pigment, TiO2 is characterized by its high opacity, brightness, and excellent durability. The production of titanium dioxide involves a series of complex processes that ensure its quality and utility across different sectors, ranging from paints and coatings to plastics and pharmaceuticals.

Understanding Titanium Dioxide R996

Titanium dioxide R996 is a specific grade manufactured with meticulous attention to quality. It is produced using a sulfate or chloride process, resulting in finely divided particles that are highly effective in reflecting light. The R996 grade is particularly known for its high brightness and superior opacity, making it ideal for applications requiring high-performance characteristics. The R996 designation indicates that this specific grade has been optimized for superior performance in various formulations.

One of the most significant aspects of titanium dioxide R996 is its outstanding chemical and physical stability. It exhibits excellent resistance to UV light, which not only helps maintain the integrity of products encapsulating it but also enhances the longevity of coatings and paints. As environmental concerns about products and their durability continue to increase, R996 is emerging as a preferred choice among manufacturers who prioritize sustainability and longevity.

Applications in Various Industries

In the paint and coatings industry, titanium dioxide R996 plays a crucial role as a white pigment. Its ability to provide excellent hiding power and brightness makes it indispensable in the formulation of both interior and exterior paints. The incorporation of R996 enhances the aesthetic appeal of painted surfaces while also providing a protective barrier against wear and corrosion.

titanium dioxide r 996 factory

The plastics industry also benefits from the unique properties of titanium dioxide R996. It is utilized in the production of various plastic products, providing not only coloration but also UV protection. This is particularly important in outdoor applications, where products are subjected to prolonged exposure to sunlight. The incorporation of R996 helps prevent material degradation, ensuring that plastic products maintain their structural integrity and visual appearance over time.

Furthermore, titanium dioxide R996 finds applications in the cosmetic industry, where it is used in products like sunscreens and makeup. The photostability of this grade of titanium dioxide allows for effective UV filtration, making it a popular choice among formulators aiming to enhance the protective qualities of their cosmetic products. Its non-toxic nature renders it safe for use in skincare, which is crucial in today’s health-conscious consumer market.

Environmental Considerations

The environmental impact of using titanium dioxide, particularly in the form of R996, is a topic of significant discussion. While titanium dioxide is celebrated for its durability and effectiveness, its production and disposal must be managed responsibly. Manufacturers are continually exploring ways to enhance sustainability in the production processes, focusing on reducing emissions and energy consumption.

Many companies are investing in cleaner technologies and practices aimed at minimizing the environmental footprint of titanium dioxide production. Additionally, waste management practices are being scrutinized to ensure that end-of-life products containing titanium dioxide are disposed of or recycled responsibly. This commitment to sustainability is crucial in mitigating potential negative environmental effects associated with industrial pigment production.

Conclusion

In conclusion, titanium dioxide grade R996 exemplifies the pinnacle of industrial pigments due to its remarkable properties and versatility. Its applications span a wide range of industries, proving indispensable in paints, plastics, and cosmetics. As technological advancements continue to evolve, the demand for high-performance materials like R996 is likely to grow. Moreover, with increasing environmental awareness, the focus on sustainable production practices will ensure that titanium dioxide maintains its relevance while meeting the needs of a more eco-conscious society. The ongoing development in this field promises to enhance the applications and effectiveness of titanium dioxide, paving the way for innovative solutions across various industries.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025