نوفمبر . 06, 2024 04:20 Back to list

Top Manufacturers of Synthetic Titanium Dioxide for Various Industrial Applications

The Role of Synthetic Titanium Dioxide Suppliers in Modern Industries

In recent years, synthetic titanium dioxide (TiO2) has emerged as a vital component across various industries due to its unique properties and versatile applications. As a crucial white pigment, TiO2 is primarily used in paints, coatings, plastics, and cosmetics. The increasing demand for synthetic titanium dioxide has led to the establishment of specialized suppliers who focus on producing high-quality materials tailored to meet the specific needs of different sectors.

Understanding Synthetic Titanium Dioxide

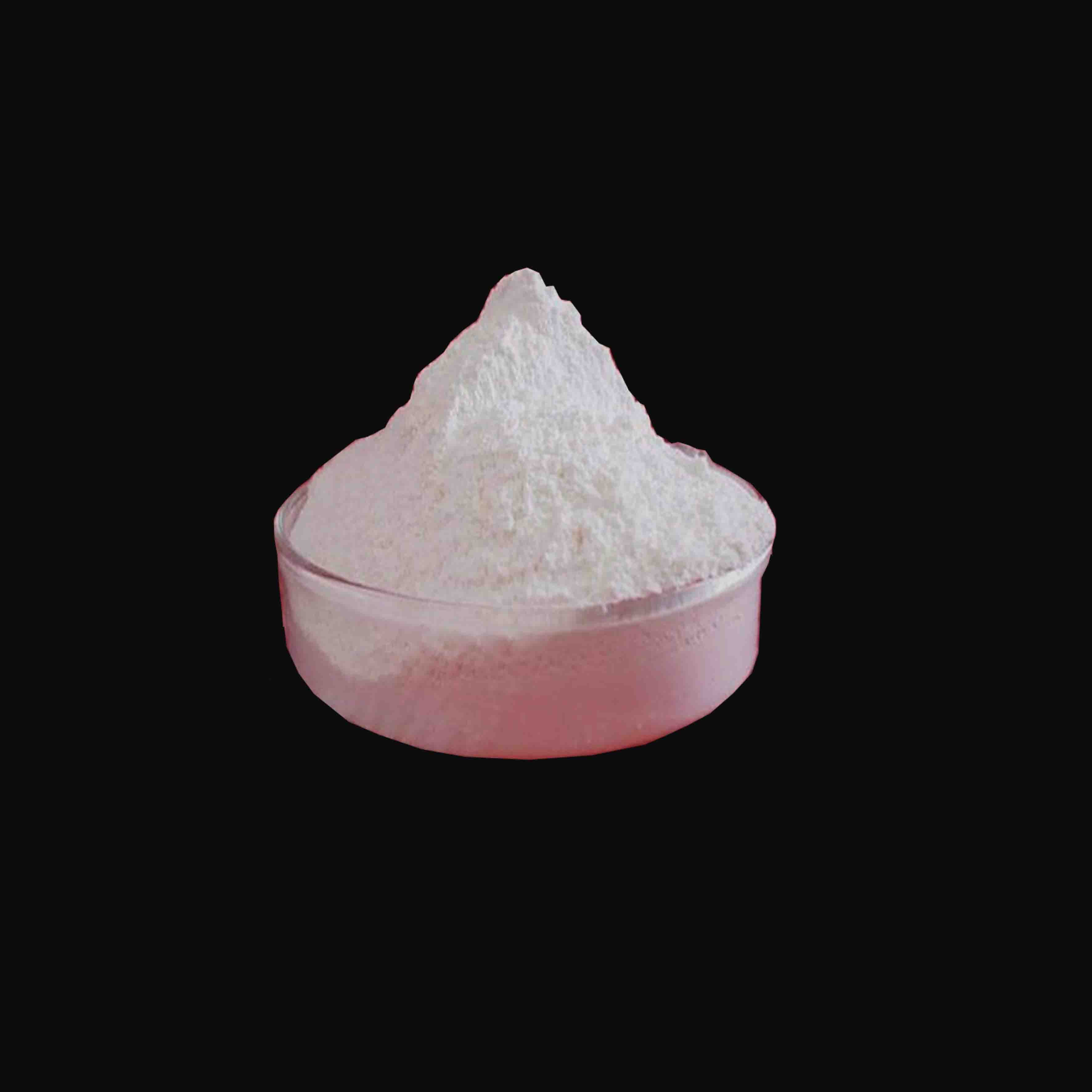

Synthetic titanium dioxide is produced through processes such as the sulfate and chloride methods, which allow for the creation of TiO2 with specific characteristics. The sulfate process generally yields a more chemically-bioactive form, whereas the chloride process results in a purer and more consistent product. The end product is a fine white powder that boasts exceptional opacity and brightness, making it an ideal choice for applications where color stability and UV resistance are critical.

One of the key advantages of synthetic titanium dioxide is its high refractive index and strong covering power, enabling it to scatter light effectively. This property makes it an ideal component in the formulation of high-quality paints and coatings, contributing to their durability and aesthetic appeal. Additionally, its non-toxic nature ensures that it is safe for use in consumer products, including food and cosmetics.

Market Demand and Supply Dynamics

The growth of industries such as construction, automotive, and personal care has propelled the demand for synthetic titanium dioxide to new heights. As these sectors continue to expand, the need for high-grade TiO2 has intensified, providing an opportunity for suppliers to innovate and improve their production processes.

Synthetic titanium dioxide suppliers play a crucial role in this ecosystem

. They are tasked with not only meeting the growing demand but also ensuring that their products comply with stringent environmental regulations. This requires a commitment to sustainable practices, including minimizing waste during production and using eco-friendly materials whenever possible.synthetic titanium dioxide supplier

Quality Assurance and Innovation

Quality assurance is paramount in the production of synthetic titanium dioxide. Suppliers invest heavily in research and development to enhance the quality of their products. This includes the improvement of particle size distribution, surface treatments, and the incorporation of advanced processing techniques. Such innovations allow suppliers to offer TiO2 that meets specific customer requirements, whether for ultra-fine applications in cosmetics or coarse applications in industrial coatings.

Moreover, suppliers are continuously exploring ways to reduce production costs and improve efficiency without compromising quality. This includes implementing advanced technology and automation in manufacturing processes. As a result, the market is witnessing the emergence of suppliers that can offer competitive prices while maintaining high standards.

Global Supply Chain and Sustainability

The global synthetic titanium dioxide market is interconnected, with suppliers often sourcing raw materials from various regions. This global supply chain has both advantages and challenges. On one hand, it allows for diversified sourcing and the ability to meet regional demands. On the other hand, it requires suppliers to navigate complexities related to transportation, tariffs, and varying regulatory environments across countries.

As environmental concerns become increasingly pressing, sustainability has become a focal point for synthetic titanium dioxide suppliers. Many companies are adopting greener practices, such as recycling production waste and reducing energy consumption in their facilities. Furthermore, some suppliers are exploring alternative methods for TiO2 production that are less harmful to the environment.

Conclusion

In summary, synthetic titanium dioxide suppliers play a pivotal role in several industries, providing a product that is indispensable for a multitude of applications. As demand continues to rise, suppliers must navigate market dynamics while prioritizing quality, innovation, and sustainability. By embracing new technologies and practices, synthetic titanium dioxide suppliers not only enhance their product offerings but also contribute to a more sustainable and environmentally friendly future. The ongoing evolution in this sector promises to fuel further advancements and adaptations that will meet the ever-changing needs of global markets.

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025