removing titanium dioxide from surfaces

فبراير . 11, 2025 17:41 Back to list

removing titanium dioxide from surfaces

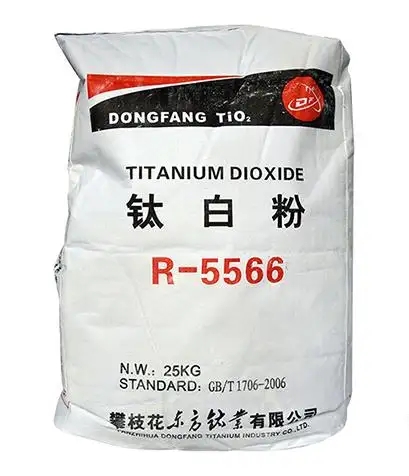

Removing titanium dioxide (TiO2) from surfaces effectively and safely is a topic that attracts significant attention across various industries. Titanium dioxide, found in many products ranging from paints to sunscreens, can pose challenges when its residues must be eliminated. This guide offers authoritative insights into techniques and products that ensure clean surfaces without compromising safety or performance.

Surface Assessment Before selecting a removal method, it is imperative to assess the surface type, TiO2 concentration, and any potential damage risks. This assessment informs the choice of products and techniques, ensuring the preservation of surface integrity during the cleaning process. Protective Measures Employ appropriate protective measures, including ventilation, personal protective equipment, and containment strategies to minimize exposure risks and environmental impact. Documentation and Compliance Adhering to industry standards and regulations regarding chemical use and waste disposal is crucial in maintaining practice integrity. Detailed documentation of cleaning processes not only ensures regulatory compliance but also contributes to the knowledge base for future projects. Trust and Expertise Partnering with industry professionals who have proven expertise in TiO2 removal is essential for successful outcomes. Leveraging their experience minimizes trial-and-error approaches, saving time and resources while delivering superior results. Professionals in this space also provide insights into the latest technologies and adaptations in cleaning methods. Future Outlook As nanotechnology and material science advance, the methods for removing titanium dioxide continue to evolve. Innovations in cleaning solutions are emphasizing greater safety and ecological considerations while enhancing performance and efficacy. Staying informed about these developments is key to maintaining an edge in industries reliant on the pristine cleanliness of their surfaces. In conclusion, the removal of titanium dioxide from surfaces requires a nuanced approach, integrating advanced techniques, expert guidance, and comprehensive planning. By prioritizing these elements, industries can ensure safe, efficient, and compliant cleaning operations that uphold the highest standards of quality and environmental responsibility.

Surface Assessment Before selecting a removal method, it is imperative to assess the surface type, TiO2 concentration, and any potential damage risks. This assessment informs the choice of products and techniques, ensuring the preservation of surface integrity during the cleaning process. Protective Measures Employ appropriate protective measures, including ventilation, personal protective equipment, and containment strategies to minimize exposure risks and environmental impact. Documentation and Compliance Adhering to industry standards and regulations regarding chemical use and waste disposal is crucial in maintaining practice integrity. Detailed documentation of cleaning processes not only ensures regulatory compliance but also contributes to the knowledge base for future projects. Trust and Expertise Partnering with industry professionals who have proven expertise in TiO2 removal is essential for successful outcomes. Leveraging their experience minimizes trial-and-error approaches, saving time and resources while delivering superior results. Professionals in this space also provide insights into the latest technologies and adaptations in cleaning methods. Future Outlook As nanotechnology and material science advance, the methods for removing titanium dioxide continue to evolve. Innovations in cleaning solutions are emphasizing greater safety and ecological considerations while enhancing performance and efficacy. Staying informed about these developments is key to maintaining an edge in industries reliant on the pristine cleanliness of their surfaces. In conclusion, the removal of titanium dioxide from surfaces requires a nuanced approach, integrating advanced techniques, expert guidance, and comprehensive planning. By prioritizing these elements, industries can ensure safe, efficient, and compliant cleaning operations that uphold the highest standards of quality and environmental responsibility.

Next:

Latest news

-

Premium Titanium Dioxide: High Purity Pigment & UV Blocker

NewsAug.10,2025

-

Rutile Titanium Dioxide for Paint Factories: Premium Industrial Grade Tio2

NewsAug.09,2025

-

Premium Titania TiO2 Manufacturer & Supplier

NewsAug.08,2025

-

Wholesale Titania TiO2 | Factory Direct Suppliers & Manufacturers

NewsAug.07,2025

-

R996 TiO2: High Performance Rutile Titanium Dioxide

NewsAug.06,2025

-

AI-Enhanced Titania Tio2 | High-Performance Solutions

NewsAug.04,2025