نوفمبر . 05, 2024 09:04 Back to list

r996 tio2 factories

The Role of R996 TiO2 Factories in the Global Market

In recent years, titanium dioxide (TiO2) has emerged as a critical component in various industries, from paint and coatings to plastics and cosmetics. Among the numerous grades of TiO2, R996 has gained prominence owing to its exceptional properties and versatility. The production of R996 TiO2 is chiefly conducted in specialized factories equipped with advanced technology to ensure purity, consistency, and quality. This article delves into the significance of R996 TiO2 factories and their impact on the global market.

Understanding R996 TiO2

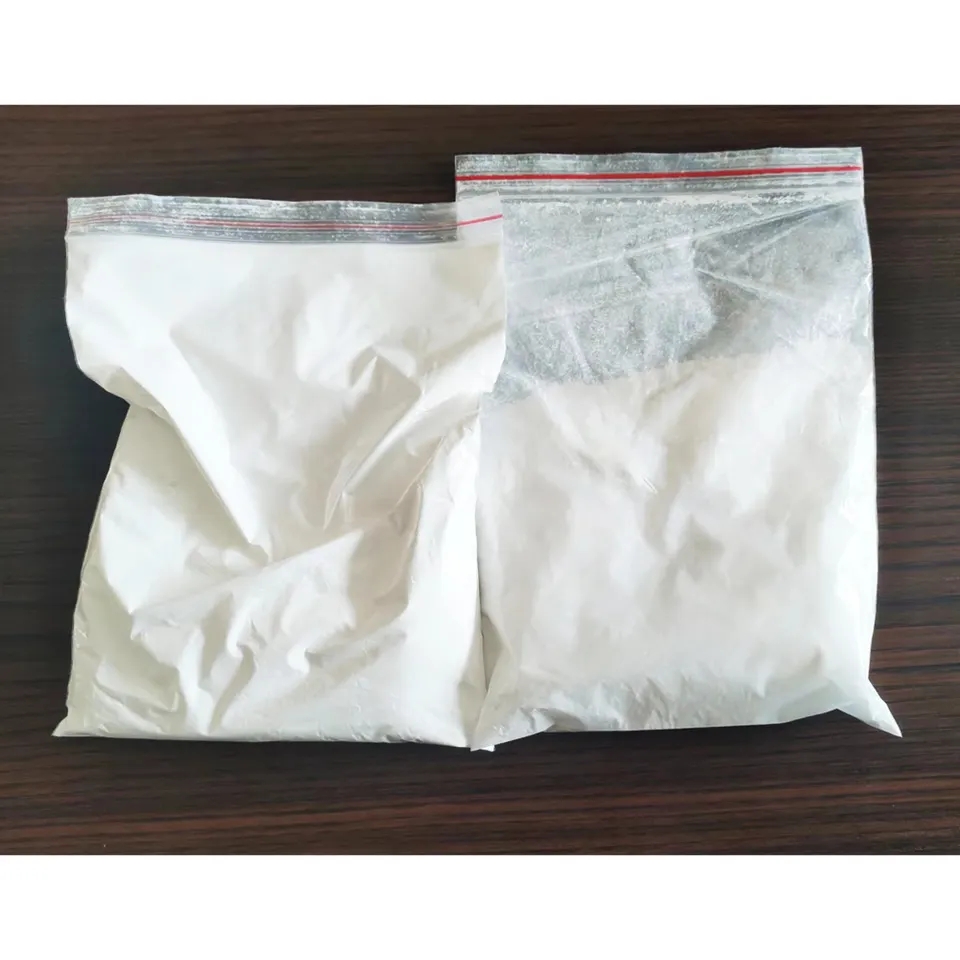

R996 is a high-quality, rutile-grade titanium dioxide produced through the sulfate process. Its characteristics, including high opacity, excellent whiteness, and UV resistance, make it an ideal choice for applications that demand superior pigmentation. The composition of R996 TiO2 allows it to reflect light in unique ways, providing not only a vibrant white hue but also durability in various environmental conditions.

The demand for R996 TiO2 is largely driven by the coatings industry, which utilizes it for its superior covering power and resistance to chalking. Additionally, the plastics industry appreciates R996 for its ability to enhance the color and brightness of products, making it a vital ingredient in manufacturing a wide array of consumer goods.

The Production Process

The production of R996 TiO2 requires an intricate process that emphasizes quality control and environmental compliance. The sulfate process used in creating R996 involves the following steps

1. Sulfate Digestion Titanium-bearing ores, primarily ilmenite, are digested in sulfuric acid at high temperatures, extracting titanium in the form of soluble titanium sulfate. 2. Separation and Purification The resulting solution undergoes a series of chemical treatments to remove impurities, ensuring that only high-quality titanium compounds remain for further processing. 3. Precipitation From the purified solution, titanium hydroxide is precipitated, which is then filtered and washed to eliminate residual impurities. 4. Calcination The final step involves heating the titanium hydroxide at elevated temperatures to produce titanium dioxide. The resulting R996 grade TiO2 is characterized by its high purity, fineness, and consistency.

r996 tio2 factories

The factories producing R996 TiO2 invest significantly in research and development to refine these processes, aiming for greater efficiency and sustainability. Innovation in production techniques not only minimizes waste but also reduces energy consumption, contributing to a lower carbon footprint.

Economic Impact and Global Supply Chain

The R996 TiO2 factories play a crucial role in the global economy. With the growing demand for high-performance materials, these factories contribute significantly to the supply chain in various sectors. The Asia-Pacific region, particularly China, dominates the production landscape due to its extensive mineral resources, well-established manufacturing facilities, and labor availability. However, countries like the United States, Europe, and India are also emerging as key players in the R996 TiO2 market, focusing on technological advancements and sustainable practices.

The economic impact of R996 TiO2 production extends beyond manufacturing alone. The availability of high-quality TiO2 supports various downstream industries, including automotive, construction, and consumer goods, ultimately driving economic growth and job creation. Additionally, as consumers increasingly demand environmentally friendly products, R996 TiO2 factories are adapting by exploring sustainable practices and product development.

Challenges and Future Directions

Despite the promising aspects, R996 TiO2 factories face challenges such as fluctuating raw material costs and stringent environmental regulations. The industry must continuously innovate to streamline operations and meet sustainability goals, which requires substantial investment in technology and training.

Looking ahead, the trend towards eco-friendly and sustainable products will shape the future of R996 TiO2 factories. Companies that focus on sustainable sourcing of raw materials, efficient waste management, and innovative production methods are likely to thrive. As the global market continues to evolve, R996 TiO2 factories must adapt to these changes, positioning themselves as leaders in the production of high-quality titanium dioxide.

In conclusion, R996 TiO2 factories are pivotal in the global supply chain, supporting numerous industries with high-quality titanium dioxide. As the demand for this versatile material grows, the factories must evolve to overcome challenges, embrace sustainability, and continue their vital role in the market.

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025