سبتمبر . 22, 2024 14:43 Back to list

lithopone in pigment manufacturers

The Role of Lithopone in Pigment Manufacturing

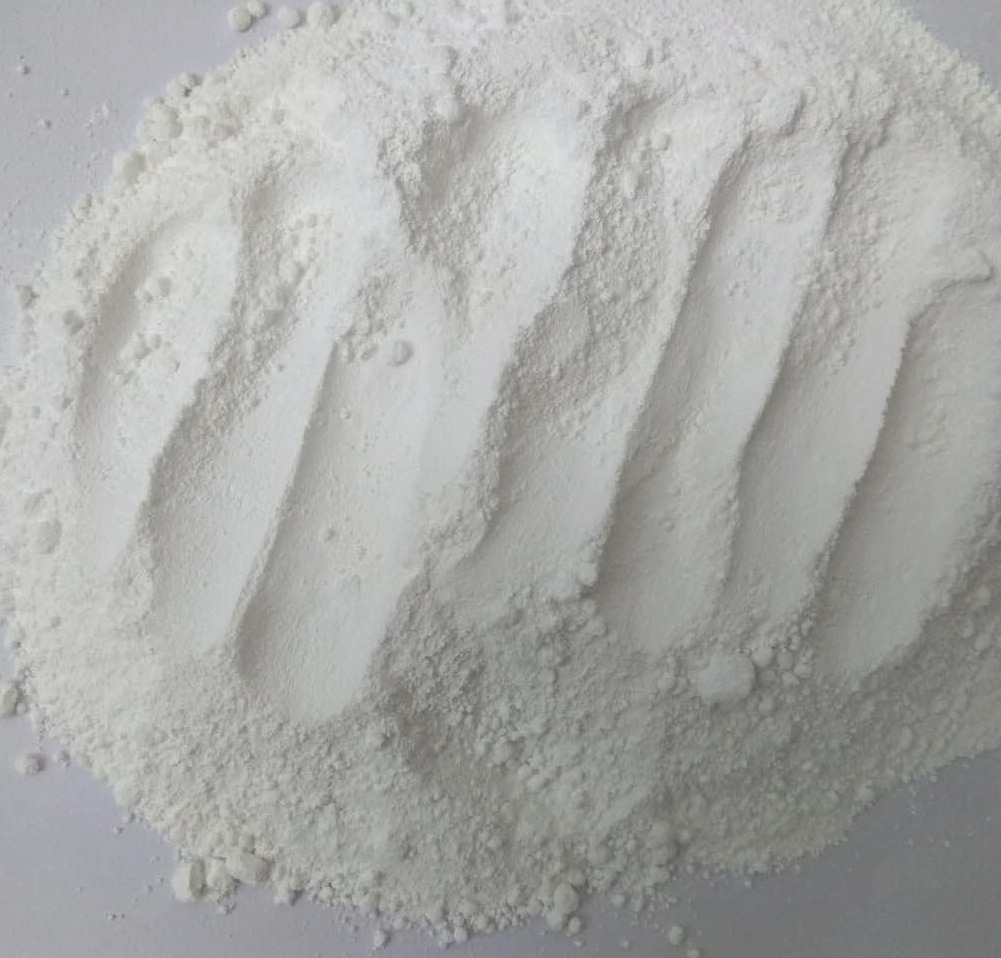

Lithopone, a pigment composed of zinc sulfide and barium sulfate, has played a significant role in the pigment industry since its introduction in the early 20th century. With its excellent opacity, brightness, and resistance to discoloration, lithopone remains a popular choice for manufacturers producing a variety of coatings, plastics, and other materials requiring high-quality pigments.

The Role of Lithopone in Pigment Manufacturing

In pigment manufacturing, lithopone is valued for its stability and non-toxic nature. Unlike some pigments that contain heavy metals, lithopone presents fewer environmental and health hazards, making it an attractive choice for manufacturers adhering to stringent safety regulations. This aligns with the growing trend toward eco-friendly materials across various industries and the rising consumer demand for sustainable products.

lithopone in pigment manufacturers

The manufacturing process of lithopone involves several steps, starting with the reaction of zinc sulfide and barium sulfate along with specific additives to enhance its performance characteristics. This complex process allows manufacturers to tailor lithopone formulations to meet the specific needs of their customers. Variations in particle size, surface treatment, and the ratios of its constituent compounds can significantly impact its performance in different applications.

Lithopone is extensively utilized in coatings, paints, and plastics. In paints and coatings, lithopone can provide excellent coverage and a bright white finish, enhancing the aesthetic appeal of the final product. In plastics, it not only serves as a colorant but also enhances the material's properties, including UV resistance and durability. Moreover, its compatibility with various polymer systems allows for its use in a wide range of formulations, further expanding its applicability in the industry.

The global market for lithopone is expected to grow steadily, driven by increasing demand from construction, automotive, and consumer goods sectors. As industries evolve and adopt new technologies, manufacturers of lithopone pigments must continue innovating to maintain their competitive edge. Research into more efficient production methods and the development of new lithopone formulations could result in even greater applications for this versatile pigment.

In conclusion, lithopone plays a crucial role in the pigment manufacturing industry, offering a unique combination of properties that cater to various applications. Its economic benefits, paired with stability and safety advantages, make it a go-to choice for many manufacturers. As demand for sustainable and high-performance materials continues to rise, lithopone is poised to strengthen its position in the market, helping to propel innovations in pigment technology well into the future.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025