يوليو . 29, 2024 23:52 Back to list

Exploring the Production Process of Brilliant Blue FCF and Titanium Dioxide in Manufacturing Industries

Brilliant Blue FCF and Titanium Dioxide The Intersection of Color and Industry

The vibrant, synthetic dye known as Brilliant Blue FCF, identified by its chemical designation E133, is widely used in the food, pharmaceutical, and cosmetic industries. This vivid blue dye not only enhances the aesthetic appeal of various products but also plays a crucial role in branding and consumer perception. Similarly, titanium dioxide (TiO2), a compound known for its remarkable opacity and brightness, is extensively employed in a multitude of applications, from paints and coatings to food products and personal care items. In this article, we will explore the factories producing Brilliant Blue FCF and titanium dioxide, their production processes, and the implications for both industry and consumer safety.

Understanding Brilliant Blue FCF

Brilliant Blue FCF is a synthetic dye derived from coal tar and is predominantly used in food products such as beverages, candies, and dairy products. Its vibrant hue not only captures attention but also enhances the perceived quality of products, as consumers often associate bright colors with freshness and desirability. However, the production of Brilliant Blue FCF is not without its controversies. There are ongoing debates regarding its safety, with concerns about potential allergic reactions and hyperactivity in children. This has led to regulatory bodies in some countries imposing restrictions on its use, prompting manufacturers to explore alternative natural colorants.

The Role of Titanium Dioxide

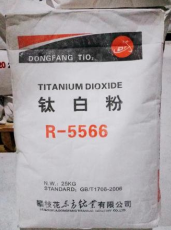

Conversely, titanium dioxide is most well-known for its use as a pigment. Its exceptional whiteness and brightness make it a staple in the paint and coatings industry, where it is used to impart opacity and durability. In the food industry, titanium dioxide serves as a whitening agent in products such as sauces and confectionery. Moreover, its UV-filtering properties have made it an essential ingredient in sunscreens and other cosmetic products, where it offers protection against harmful rays.

brilliant blue fcf titanium dioxide factories

The Manufacturing Process

The production process for both Brilliant Blue FCF and titanium dioxide involves several stages. For Brilliant Blue FCF, manufacturers begin with the synthesis of colorants through complex chemical reactions, often involving the use of solvents and other reagents. Controlling the reaction conditions is crucial to ensuring the purity and quality of the dye, which is then purified, dried, and packaged for distribution.

On the other hand, the production of titanium dioxide primarily involves the sulfate or chloride process. In the sulfate process, titanium ores are treated with sulfuric acid to produce titanium sulfate, which is then hydrolyzed to form titanium dioxide. The chloride process is more efficient and involves reacting titanium ores with chlorine gas, yielding titanium tetrachloride, which is then oxidized to produce titanium dioxide. After the production phase, extensive quality control measures are taken to ensure that both Brilliant Blue FCF and titanium dioxide meet the required safety and quality standards.

Implications for Industry and Safety

As consumers become increasingly conscious of the ingredients in their products, the demand for transparency in manufacturing practices has surged. Factories producing these compounds must adhere to stringent regulations and quality standards to ensure product safety. Moreover, the rise of green chemistry has prompted some manufacturers to invest in more sustainable practices, exploring environmentally friendly alternatives for synthetic dyes and pigments.

In conclusion, the factories producing Brilliant Blue FCF and titanium dioxide inhabit a critical space in the broader industrial landscape. These compounds not only enhance the visual appeal of products but also raise important questions about safety and sustainability. As the industry evolves, it will be essential for stakeholders to balance innovation with consumer safety, ensuring that the products reaching the market are both appealing and safe for all. The future of color and functionality in products may well rely on the advancements made in these manufacturing processes.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025