ديسمبر . 15, 2024 03:23 Back to list

colour of titanium dioxide manufacturer

The Color of Titanium Dioxide Insights from Manufacturers

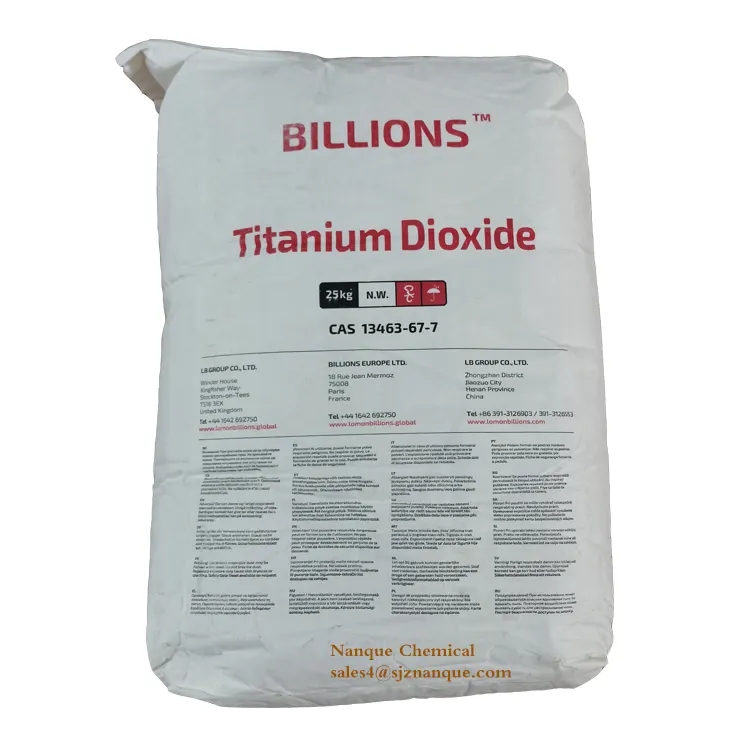

Titanium dioxide (TiO2) is one of the most widely used white pigments in the world, known for its exceptional brightness and high refractive index. It serves a multitude of applications across various industries, including paint, coatings, plastics, paper, and cosmetics, among others. This article explores the aspects related to the color of titanium dioxide, focusing on its manufacturing process, properties, and the significance of color quality in different applications.

Understanding Titanium Dioxide

Titanium dioxide occurs naturally in various mineral forms such as rutile and anatase, but the synthetic production of TiO2 substantially dominates the market. The unique properties of titanium dioxide stem from its high opacity and excellent light-scattering ability, making it an ideal choice for applications requiring bright white coloring. However, the color quality of titanium dioxide can vary based on the manufacturing process and treatment techniques employed by producers.

Manufacturing Processes

The manufacturing of titanium dioxide primarily occurs through two processes the sulfate process and the chloride process.

1. Sulfate Process This involves the reaction of titanium ore with sulfuric acid, resulting in the formation of titanium sulfate, which is then hydrolyzed to produce titanium dioxide. This process tends to produce a product with finer particle sizes and can often incorporate the possibility of producing different grades. However, it generates more waste and can be less environmentally friendly.

2. Chloride Process This method involves burning titanium ores in a chlorine environment to produce titanium tetrachloride, which is then oxidized to form titanium dioxide. This process is typically considered more efficient and environmentally friendly due to lower waste generation and better purity control in the final product.

colour of titanium dioxide manufacturer

The Importance of Color Quality

Despite its primary use as a white pigment, the color quality of titanium dioxide is paramount for the industries that rely on it. Manufacturers must ensure consistent color performance to meet the specific needs of their customers. Variations in color can influence the perception of product quality and can alter the performance characteristics, particularly in applications like coatings and paints.

1. Pigment Strength The effectiveness of titanium dioxide as a pigment heavily depends on its color properties. Tighter control over the standards of white point, brightness, and color purity is critical, as these factors directly impact the opacity and coverage provided by the pigment in finished products.

2. Color Stability The stability of the color over time is essential for industries such as cosmetics and paints, where color fading can compromise the aesthetic appeal of products. Manufacturers utilize various treatments during the production of titanium dioxide, such as surface coatings, to enhance color stability and prevent photodegradation.

3. Specialty Applications In addition to its role as a white pigment, manufacturers have also developed colored grades of titanium dioxide for specialty applications. These colored variants are commonly employed in areas such as plastics and coatings, where specific hues are desired without compromising the benefits associated with titanium dioxide, such as UV resistance or durability.

Conclusion

The color of titanium dioxide is a critical factor in its application across various industries, emphasizing the need for manufacturers to maintain stringent quality control during production. Through understanding the different manufacturing processes and considering the importance of color stability and effectiveness, manufacturers are able to cater to the diverse needs of their clients. As industries continue to evolve, so too will the innovations in titanium dioxide production, ensuring that it remains a valuable and versatile material in the global marketplace.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025