نوفمبر . 10, 2024 09:00 Back to list

Barium Sulfate Use in Paint Production and Its Impact on Factory Operations

The Role of Barium Sulphate in Paint Factories

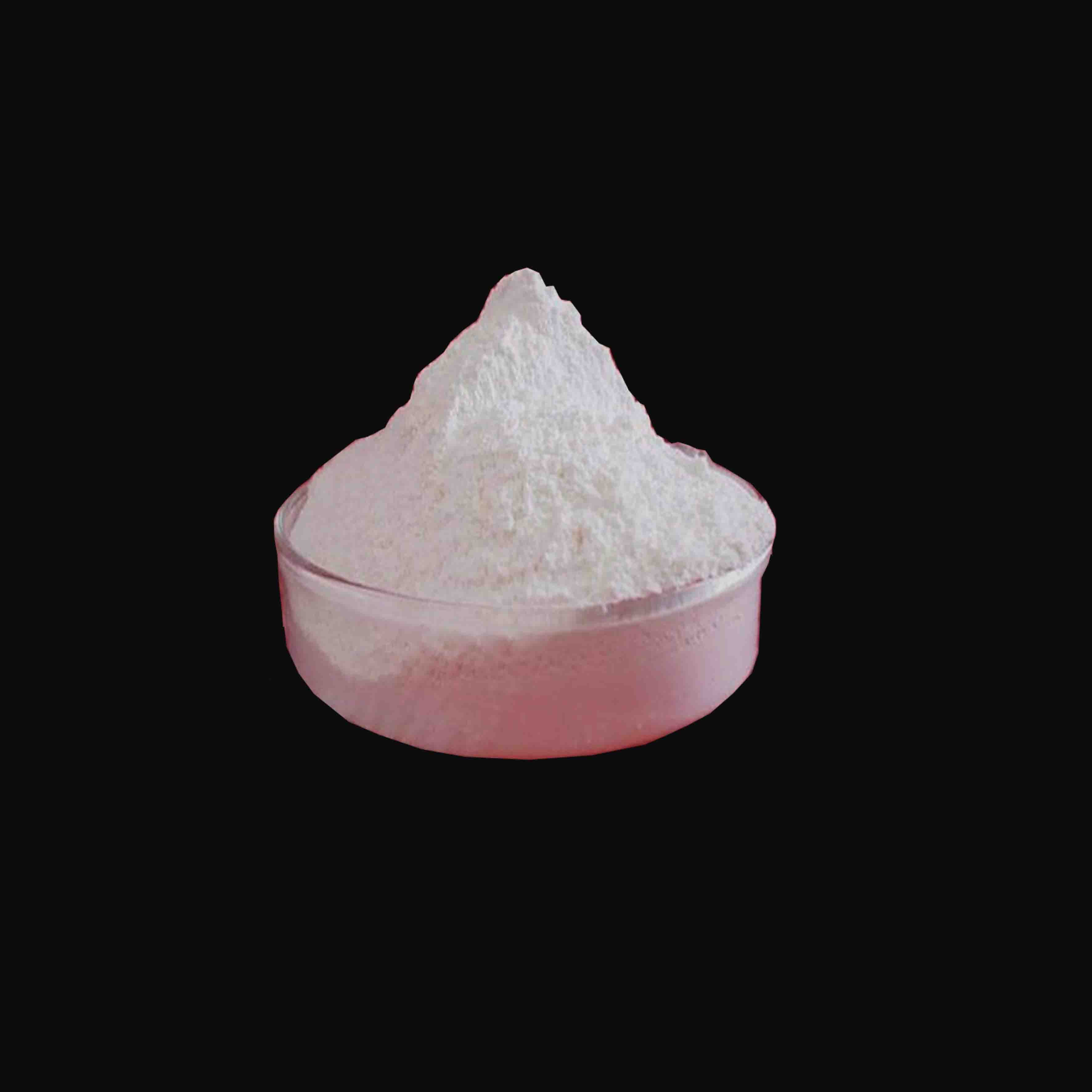

Barium sulphate, a white crystalline compound with the chemical formula BaSO₄, is a vital ingredient widely used in various industrial applications, particularly in the manufacturing of paints and coatings. Renowned for its excellent opacity, brightness, and chemical inertness, barium sulphate plays a significant role in enhancing the performance and aesthetic qualities of paints produced in factories.

Properties and Functions of Barium Sulphate

One of the most pivotal properties of barium sulphate is its high pigment volume concentration, which contributes to the opacity of paint. When added to paint formulations, it acts as a filler that improves coverage and reduces the amount of binder required to achieve the desired consistency. This not only enhances the efficiency of the paint but also lowers the production costs.

Barium sulphate is particularly valued for its non-toxic nature, making it a preferred choice in industries focused on sustainability and safety. Unlike other fillers that may contain harmful substances, barium sulphate can be safely used in paints for both interior and exterior applications, including those for residential and commercial buildings. This aspect aligns with the growing emphasis on environmentally friendly products in the paint industry.

Moreover, barium sulphate is characterized by its excellent chemical stability. It does not dissolve in water or neutral solvents, ensuring that it remains inert during the drying process of paints. This property is crucial because it prevents any chemical reactions that could compromise the quality of the paint or lead to undesirable effects such as color shift or degradation over time.

Applications in Paint Manufacturing

In paint factories, barium sulphate is employed in various formulations, including wall paints, industrial coatings, and specialty products such as automotive paints. In wall paints, barium sulphate contributes to a smooth finish while enhancing durability and resistance to abrasion. As a result, painted surfaces are not only visually appealing but also maintain their integrity under various environmental conditions.

barium sulphate in paint factories

Additionally, barium sulphate's high refractive index allows for better light scattering, which further enhances the brightness and color retention of the paint. This is particularly important in applications where vibrant colors are essential, such as in consumer goods and decorative coatings.

In industrial coatings, barium sulphate serves a dual purpose. It not only acts as a pigment but also helps improve the mechanical properties of the coating, such as hardness and adhesion. These enhancements are critical for protective coatings applied in harsh environments, where resistance to chemicals, moisture, and ultraviolet light is paramount.

Regulatory Considerations

Although barium sulphate is considered non-toxic and safe, regulatory bodies still monitor its use in various applications. Manufacturers must ensure compliance with environmental regulations and safety standards, particularly in regions where stricter guidelines are enforced. This can include adhering to limits on heavy metals and other contaminants in paint formulations.

Furthermore, as consumer awareness regarding the safety of products continues to grow, paint manufacturers are increasingly required to disclose the ingredients used in their formulations. This trend has led to a push for transparency and the exploration of alternative materials that can replace traditional fillers while maintaining performance.

Conclusion

In conclusion, barium sulphate plays an indispensable role in paint factories, providing essential benefits such as improved opacity, brightness, and mechanical properties. Its non-toxic, chemically stable nature aligns with modern demands for sustainable and safe industrial practices. As the paint industry continues to evolve, barium sulphate will undoubtedly remain a key component in the formulation of high-quality paints and coatings, ensuring that they meet both aesthetic desires and performance requirements. With ongoing innovations and regulatory considerations, the future of barium sulphate in the paint industry looks promising, paving the way for advanced formulations that cater to a wide range of applications.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025