PRODUKVERTONING

Integriteitsbestuur, voldoende voorraad, perfekte na-verkope diens, produkte van hoë gehalte, billike pryse en deurdagte diens.

spesifikasie

Integriteitsbestuur, voldoende voorraad, perfekte na-verkope diens, produkte van hoë gehalte, billike pryse en deurdagte diens.

*Gives white coatings maximum brightness and neutral tones,

*Produces bright, clean shades.

*Disperses easily and meets all requirements of modern production methods.

*Has very high hiding power and is therefore very economical to use.

*Produces low-haze, high-gloss coatings.

*Suitable for all oil-based, solvent-based and water-based paints and coatings for outdoor use.

Bedryfspesifieke eienskappe

| CAS No. | 13463-67-7 |

| Reinheid | 98% |

Ander eienskappe

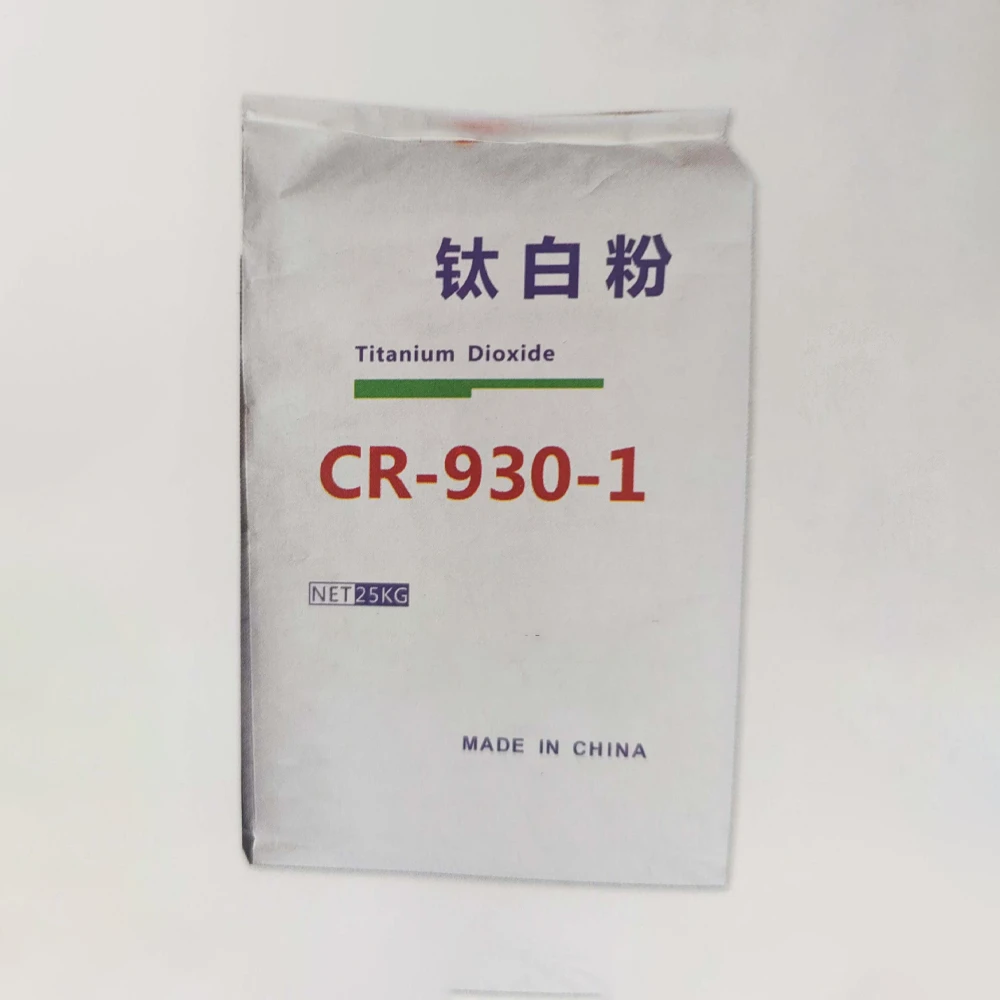

| Klassifikasie | Titaandioksied |

| Plek van oorsprong | Hebei, China |

| Ander name | Anatase Titaandioksied |

| MF | TiO2 |

| EINECS No. | 236-675-5 |

| Graad Standaard | Industriële Graad |

| Voorkoms | Wit poeier |

| Toepassing | coating, drukink, seksie, plastiek |

| Produk Naam | Anatase titaandioksied |

| Kleur | Wit kleur |

| Pakket | 25 kg/sakkie |

| Vorm | Poeier |

| Voorkoms | Wit |

| Sleutelwoorde | Wit poeier Tio2 Titaandioksied |

| Graad | Industrail Graad |

| Gebruik | Bedekkings Drukink.plastiek |

| Ander name | Tio2 |

Lei tyd

| Hoeveelheid (kilogram) | 1 - 25 | 26-1000 | 1001 -25000 | >25 000 |

| Leityd (dae) | 5 | 7 | 15 | Om te onderhandel |

Rutile and anatase are two common crystal forms of titanium dioxide(Tio2), and they exhibit distinct properties that make them suitable for different applications. The primary differences between rutile and anatase titanium dioxide lie in their crystal structures, optical properties, and performance characteristics. Here's a breakdown of the key distinctions:

Kristalstruktuur:

Rutile Titanium Dioxide (r-TiO2): Rutile has a tetragonal crystal structure. It is characterized by well-defined, elongated crystals and is thermodynamically more stable than anatase.

Anatase Titaandioksied (a-TiO2): Anatase het 'n ander tetragonale kristalstruktuur. Sy kristalle is tipies meer afgerond en minder goed gedefinieer as rutielkristalle.

Kleur en deursigtigheid:

Rutiel: Rutile TiO2 is bekend vir sy hoër brekingsindeks, wat lei tot groter ondeursigtigheid en witheid. Dit bied beter bedekking en wegkruipkrag, wat dit geskik maak vir toepassings waar ondeursigtigheid van kardinale belang is, soos in verf en bedekkings.

Anatase: Anatase TiO2 het 'n effens laer brekingsindeks as rutiel. Terwyl dit nog wit is, vertoon dit oor die algemeen minder ondeursigtigheid in vergelyking met rutiel. Anatase word dikwels gebruik in toepassings waar hoë ondeursigtigheid nie 'n primêre vereiste is nie, soos in sekere skoonheidsmiddels en fotokatalisators.

Fotokatalitiese aktiwiteit:

Rutiel: Rutiel TiO2 het oor die algemeen laer fotokatalitiese aktiwiteit in vergelyking met anatase. Dit maak rutiel meer geskik vir toepassings waar fotokatalise, soos selfreinigende oppervlaktes, nie verlang word nie.

Chemiese stabiliteit:

Rutiel: Rutiel is chemies en termies meer stabiel. Dit is minder reaktief as anatase, wat dit geskik maak vir gebruik in omgewings waar stabiliteit noodsaaklik is, soos in buitebedekkings.

Anatase: Anatase is meer reaktief en kan hoër fotokatalitiese aktiwiteit toon. Hierdie eienskap word dikwels gebruik in toepassings soos fotokatalise vir lugsuiwering en waterbehandeling.

Koste:

Rutiel: Rutiel TiO2 word oor die algemeen as duurder as anatase beskou as gevolg van sy voortreflike eienskappe en stabiliteit. Die keuse tussen rutiel en anatase kan egter ook afhang van die spesifieke vereistes van die toepassing.

Application of Titanium Dioxide in Paints and Coatings

Architectural coatings: In interior architectural coatings, titanium dioxide is used to create various light and white finishes. It provides a good hiding power for the paint and ensures that the wall looks even and smooth. For building exterior wall coatings, its weatherability is very important. It helps paint to keep its color and durability, and protects buildings from bad weather for a long time.

Automotive coatings: In the automotive industry, titanium dioxide coatings are used in primer and varnish formulations. In the primer, it provides the required color and opacity, whether it is bright white car topcoat or light metallic paint. In the transparent coating, it can enhance the overall appearance and durability of the coating, protect the underlying pigment from ultraviolet damage, and maintain the aesthetic appeal of the vehicle.

Industrial coatings: industrial coatings, such as those used in machinery, equipment and metal structures, rely on the corrosion resistance and hiding power of titanium dioxide coatings. By providing a thick opaque layer, it helps to protect the metal surface from rust and other forms of corrosion. In addition, the high whiteness and color stability of titanium dioxide ensure that industrial equipment can be kept clean and well maintained even after long-term use.

Importance of Titanium Dioxide in Paints and Coatings

In the field of paints and coatings, titanium dioxide plays an extremely key role, and its importance is mainly reflected in providing whiteness and hiding power (that is, opacity), which is based on the following two key reasons.

On the one hand, titanium dioxide has a high refractive index, and titanium dioxide particles with appropriate size can efficiently scatter visible light with wavelength in the range of λ ≈ 380-700 nm. On the other hand, titanium dioxide itself is white and hardly absorbs visible light.

These two characteristics enable it to effectively scatter and reflect light, greatly improve the overall quality and performance of paint, and then become an indispensable part of various paint formulations such as architectural coatings and automobile coatings.

From the point of view of optical characteristics, in systems such as paints and coatings, the role of titanium dioxide is to change the optical characteristics of the system. The phenomena that control the optical properties of particles in these systems mainly include absorption, reflection and refraction, and scattering.

In terms of absorption, the particles in the system can interact with visible light, and the degree of light absorption by particles depends on the chemical composition of molecules inside the particles. For example, if a particle contains a specific chromophore, it may absorb light with a specific wavelength, thus affecting the color expression of the whole paint or coating.

Key Points of Realizing Effective Titanium Dioxide Pigments Scattering

Particle size control: the scattering effect is the best when the particle size is 0.2-0.3 micron, which can be accurately controlled by chemical vapor deposition, liquid precipitation and other processes. For example, in liquid phase precipitation, the temperature, reactant concentration and reaction time are strictly controlled to make the particles grow more evenly.

Optimization of dispersion: adding dispersant, its molecules can be adsorbed on the surface of particles and react with coating solvent or resin to make particles evenly dispersed. You can also use high-speed stirring, ball milling and other equipment to break the agglomeration through shear force and grinding.

Suitable coating system: Different coatings have different chemical compositions and physical properties, so titanium dioxide pigments with suitable surface treatment should be selected. For example, water-based coatings are treated with hydrophilicity, and solvent-based coatings have good affinity with organic solvents to ensure their stable dispersion in coatings.

Reflection and refraction occur at the interface of the two materials. In paints and coatings, titanium dioxide particles form many interfaces with surrounding media (such as solvents, resins, etc.). The reflection and refraction at these interfaces affect the propagation path and intensity of light in the system, and then affect the gloss and transparency of the coating.

besigheids profiel

Integriteitsbestuur, voldoende voorraad, perfekte na-verkope diens, produkte van hoë gehalte, billike pryse en deurdagte diens.

verpakking aflewering

Integriteitsbestuur, voldoende voorraad, perfekte na-verkope diens, produkte van hoë gehalte, billike pryse en deurdagte diens.

maatskappy styl

Integriteitsbestuur, voldoende voorraad, perfekte na-verkope diens, produkte van hoë gehalte, billike pryse en deurdagte diens.