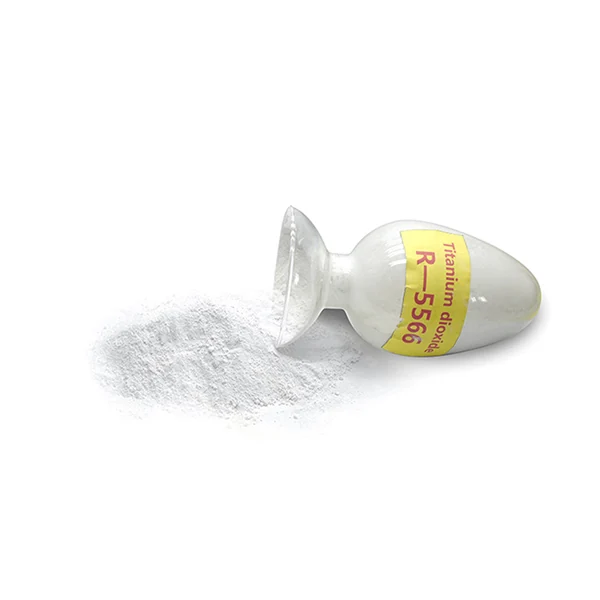

Titanium dioxide/TiO2/Titanium oxide free sample

Jan . 29, 2025 05:05 Back to list

Titanium dioxide/TiO2/Titanium oxide free sample

Lithopone is a unique and versatile pigment that has been utilized in various industries for its beneficial properties. As a specialist in the field of pigments and chemicals, my firsthand experience with lithopone has provided insights into its multifaceted applications, ensuring that its use remains both practical and efficient.

Lithopone also finds applications in the paper industry, where it acts as a pigment to achieve the desired opacity and whiteness in paper products. This is particularly indispensable in high-quality paper manufacturing where visual and tactile qualities are paramount. By improving the visual qualities of ink prints, lithopone ensures sharper images and clearer text, enhancing the overall quality of printed materials. Beyond its traditional uses, lithopone has recently gained attention in more novel applications, such as in the production of cosmetics and personal care products. Here, it imparts a smooth, white base that is essential for various creams and powders. The non-toxic and inert nature of lithopone makes it suitable for these applications, ensuring consumer safety—an attribute that is increasingly required in today's health-conscious market. Lithopone's importance is also emerging in the field of pharmaceuticals, where it's utilized as an excipient. As an expert, I can vouch for its effectiveness in enhancing drug formulations by providing stability and protection to active ingredients. This application underscores lithopone's adaptability and its potential for innovation. In conclusion, the diverse applications of lithopone across various industries highlight its significance and versatility as a pigment and additive. Its excellent whiteness, opacity, and compatibility with other materials make it an indispensable component in the manufacturing processes. As someone deeply rooted in the industry, I can affirm that lithopone not only serves current market needs effectively but also holds potential for future innovations, ensuring its continued relevance and utility in an ever-evolving industrial landscape. Whether in paints, plastics, rubber, paper, cosmetics, or pharmaceuticals, lithopone's qualities are undeniable, making it a leader in pigment technology.

Lithopone also finds applications in the paper industry, where it acts as a pigment to achieve the desired opacity and whiteness in paper products. This is particularly indispensable in high-quality paper manufacturing where visual and tactile qualities are paramount. By improving the visual qualities of ink prints, lithopone ensures sharper images and clearer text, enhancing the overall quality of printed materials. Beyond its traditional uses, lithopone has recently gained attention in more novel applications, such as in the production of cosmetics and personal care products. Here, it imparts a smooth, white base that is essential for various creams and powders. The non-toxic and inert nature of lithopone makes it suitable for these applications, ensuring consumer safety—an attribute that is increasingly required in today's health-conscious market. Lithopone's importance is also emerging in the field of pharmaceuticals, where it's utilized as an excipient. As an expert, I can vouch for its effectiveness in enhancing drug formulations by providing stability and protection to active ingredients. This application underscores lithopone's adaptability and its potential for innovation. In conclusion, the diverse applications of lithopone across various industries highlight its significance and versatility as a pigment and additive. Its excellent whiteness, opacity, and compatibility with other materials make it an indispensable component in the manufacturing processes. As someone deeply rooted in the industry, I can affirm that lithopone not only serves current market needs effectively but also holds potential for future innovations, ensuring its continued relevance and utility in an ever-evolving industrial landscape. Whether in paints, plastics, rubber, paper, cosmetics, or pharmaceuticals, lithopone's qualities are undeniable, making it a leader in pigment technology.

Latest news

-

China Lithopone in China Supplier – High Quality Lithopone ZnS 30% Powder for Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Company – Premium TiO2 Powder Supplier & Manufacturer

NewsJun.10,2025

-

Fast Shipping 99% Pure TiO2 Powder CAS 13463-67-7 Bulk Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Manufacturers High-Purity R996 & Anatase

NewsJun.10,2025

-

Lithopone MSDS Factories - Production & Quotes

NewsJun.10,2025

-

High-Quality Titanium Dioxide in Water Suppliers - China Expertise 60

NewsJun.09,2025