Okt . 16, 2024 04:33 Back to list

Top Titanium Dioxide Powder Producers for Quality Industrial Applications

The Landscape of Titanium Dioxide Powder Manufacturers An Overview

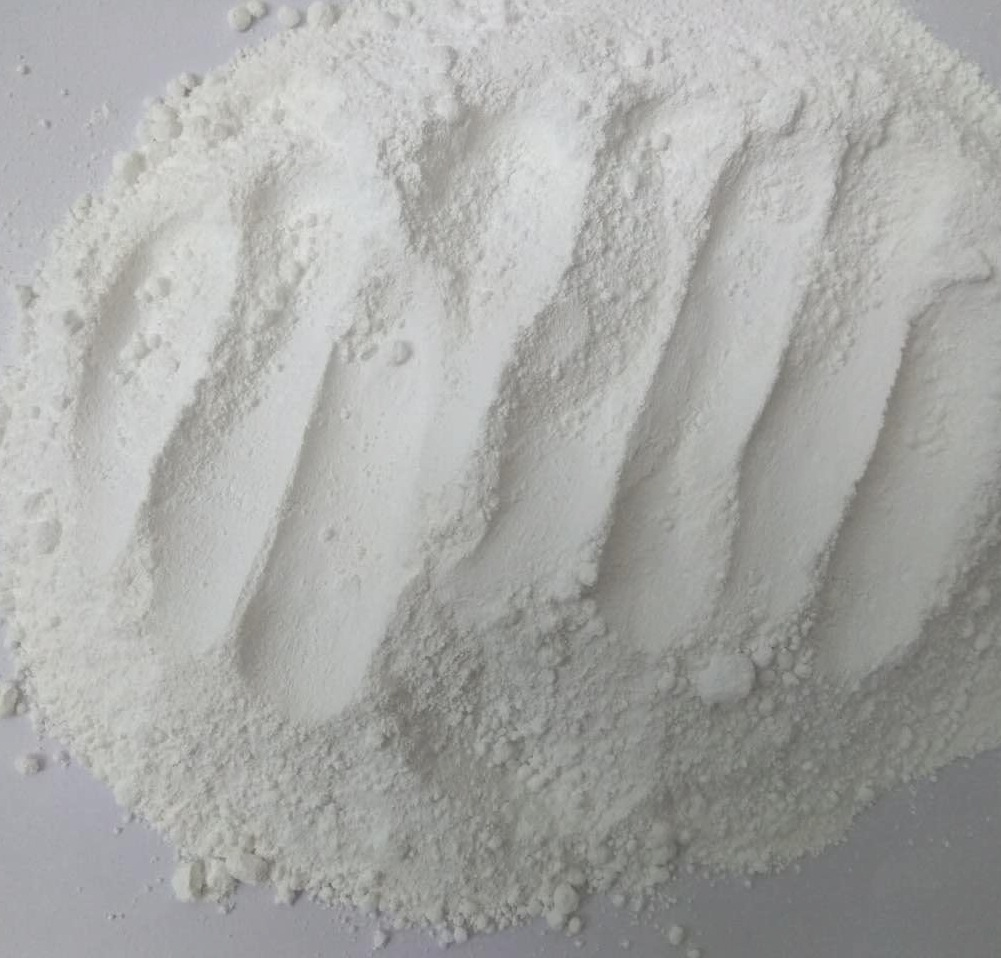

Titanium dioxide (TiO2) powder is a critical material that finds application across various industries, including paints, coatings, plastics, paper, cosmetics, and food. Its exceptional properties, such as high refractive index, excellent UV resistance, and strong opacity, make it a preferred choice for manufacturers worldwide. This article explores the landscape of titanium dioxide powder manufacturers, highlighting trends, technologies, and operational practices shaping the industry.

Understanding Titanium Dioxide

Titanium dioxide is a white pigment derived from titanium ore. The production process typically involves two primary methods the sulfate process and the chloride process. The sulfate process uses sulfuric acid to obtain TiO2, often resulting in a product with lower purity and higher production costs. In contrast, the chloride process involves the oxidation of titanium tetrachloride, yielding higher purity TiO2 and lower emissions. This has led to greater adoption of the chloride process among manufacturers seeking to enhance product quality and meet stringent environmental regulations.

Key Players in the Market

The titanium dioxide powder market is characterized by a mix of large-scale manufacturers and smaller, niche players. Some of the leading companies in this sector include Chemours, Huntsman Corporation, Tronox Limited, and Kronos Worldwide. These manufacturers have established substantial market presence due to their extensive production capabilities, strong distribution networks, and significant investments in research and development (R&D).

Emerging markets are also witnessing the rise of local manufacturers who cater specifically to regional demands. Companies in countries like China, India, and Brazil have been rapidly increasing production capacities to capitalize on growing industrial requirements. The competitive landscape in these markets is intensifying, with manufacturers focusing on cost-effectiveness and product differentiation to gain an edge.

Trends Influencing the Industry

titanium dioxide powder manufacturers

1. Sustainability Practices With increasing awareness of environmental issues, titanium dioxide manufacturers are under pressure to adopt sustainable practices. This includes reducing carbon footprints, optimizing resource efficiency, and implementing eco-friendly production processes. Many companies are exploring alternative raw materials, recycling techniques, and waste reduction strategies to align their operations with global sustainability goals.

2. Technological Advancements The ongoing advancement in production technologies has transformed the titanium dioxide manufacturing process. Innovations in nano-technology, for instance, are allowing manufacturers to produce finer grades of TiO2 with enhanced properties. These advancements not only improve product performance but also facilitate application in high-value sectors such as electronics and renewable energy.

3. Market Diversification Traditionally, the demand for titanium dioxide powder has been driven by the paint and coatings industry. However, manufacturers are increasingly diversifying their product portfolios to tap into emerging applications such as 3D printing, solar cells, and food additives. This shift is driven by the need to sustain growth and meet the evolving demands of the market.

Challenges Facing Manufacturers

Despite these positive trends, titanium dioxide powder manufacturers face several challenges. Price volatility of raw materials, especially titanium ore, can impact production costs and profitability. Additionally, stringent regulatory frameworks regarding environmental emissions and safety standards complicate compliance for manufacturers. The recent, increased scrutiny on the health impacts of certain TiO2 applications has led to calls for further research and possible product reformulation, adding another layer of complexity to daily operations.

Conclusion

As the demand for titanium dioxide powder continues to grow, manufacturers are navigating a complex landscape defined by technological evolution, sustainability imperatives, and changing market dynamics. The ability to innovate, adapt, and comply with regulatory requirements will determine the success of companies in this competitive arena. With an increasing focus on eco-friendly practices and advanced production methods, the titanium dioxide industry is poised for a promising future, ready to meet the diverse and evolving needs of its customers.

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025