Sep . 21, 2024 15:07 Back to list

titanium dioxide for paper making

Titanium Dioxide for Paper Making Enhancing Quality and Performance

Titanium dioxide (TiO2) is a versatile compound extensively used in various industries due to its unique properties. One of its significant applications is in the paper-making industry, where it serves as a vital additive that enhances the quality and performance of paper products. The use of titanium dioxide in paper production primarily revolves around its role as a pigment, improving brightness, opacity, and durability of the final product.

Titanium Dioxide for Paper Making Enhancing Quality and Performance

Opacity is another critical aspect where titanium dioxide demonstrates its effectiveness. Opacity refers to the degree to which light is prevented from passing through the paper. Higher opacity means that the text or images printed on one side of the paper will not show through to the other side, which is especially important for double-sided printing. Titanium dioxide effectively scatters light, thereby increasing the opacity of the paper without significantly increasing basis weight, allowing manufacturers to create lightweight yet high-performance products.

titanium dioxide for paper making

In addition to improving brightness and opacity, titanium dioxide also enhances the surface properties of paper. Papers treated with TiO2 exhibit better smoothness and printability, which is essential for high-quality printing. The fine particles of titanium dioxide can fill in microscopic pores on the paper surface, resulting in a smoother finish that allows for sharper and more vibrant print results. This is particularly advantageous for applications in brochures, magazines, and high-end product packaging, where printing quality is paramount.

Moreover, titanium dioxide contributes to the durability and longevity of paper products. It provides resistance to environmental degradation, such as UV light and moisture, which can cause discoloration and deterioration over time. This characteristic is particularly valuable for outdoor applications or products that are exposed to varying environmental conditions. The incorporation of titanium dioxide can help extend the lifespan of paper, making it a more sustainable choice in the long run.

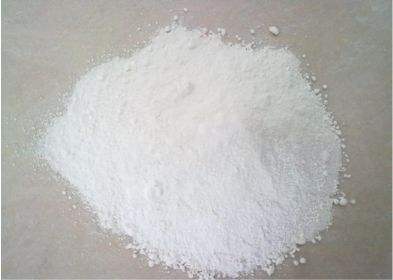

The production process of titanium dioxide for paper making typically involves high-quality mineral sources, followed by processes such as hydrometallurgy or sulfate production to obtain the desired particle size and purity. The resulting product is a fine, white powder that can be easily integrated into the paper-making process, whether in the pulp stage or as a coating.

In conclusion, titanium dioxide plays a crucial role in enhancing the quality and performance of paper products. Its ability to improve brightness, opacity, surface smoothness, and durability makes it an indispensable additive in the paper-making industry. As demand for high-quality paper continues to rise, the significance of titanium dioxide is expected to grow, solidifying its position as a key component in producing superior paper products that meet the needs of consumers and industries alike.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025