Des . 22, 2024 02:33 Back to list

titanium dioxide filler suppliers

Titanium Dioxide Filler Suppliers An Overview of the Industry

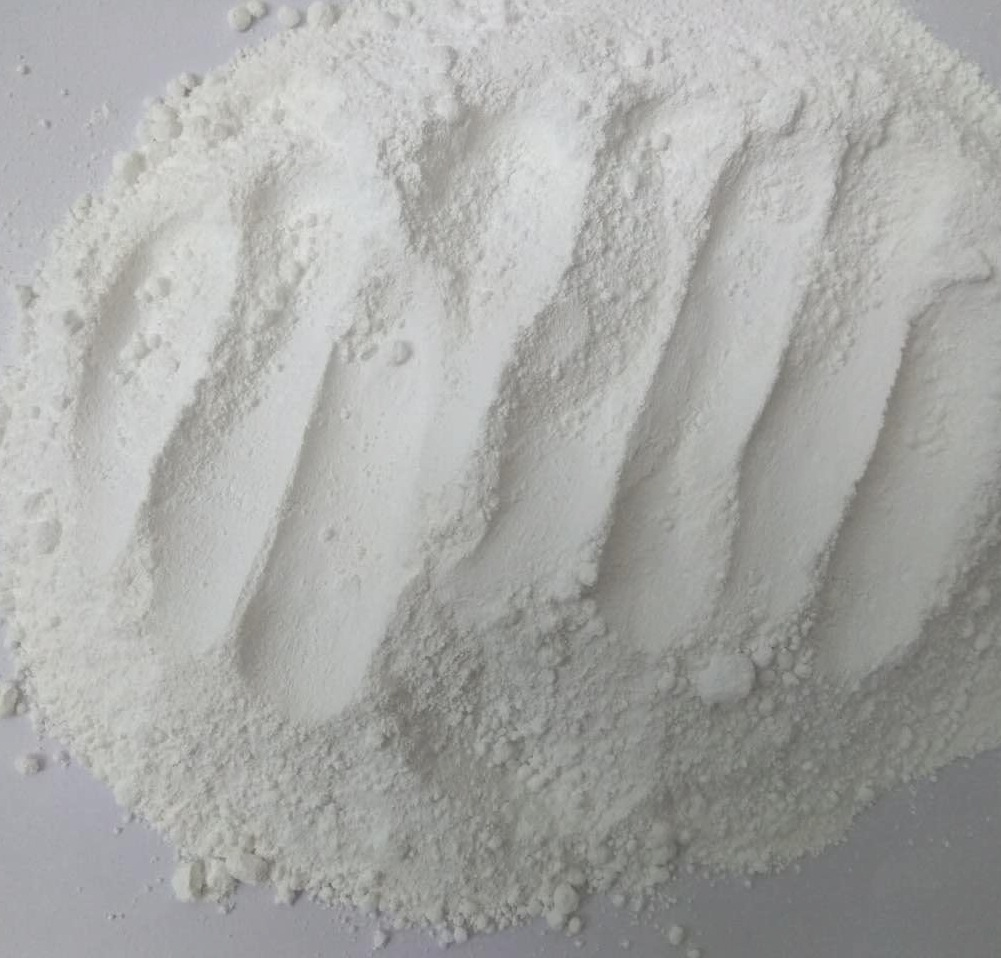

Titanium dioxide (TiO2) is a widely used white pigment and filler known for its excellent opacity, durability, and UV resistance. Found in various industrial applications, from paints and coatings to plastics, papers, and even food products, titanium dioxide has cemented its place as a key ingredient across multiple sectors. As demand for high-quality TiO2 continues to rise globally, the role of titanium dioxide filler suppliers has become increasingly critical. This article explores the landscape of titanium dioxide filler suppliers, their significance, and trends shaping the industry.

The Role of Titanium Dioxide Fillers

Titanium dioxide is primarily used as a white pigment due to its superior brightness and ability to scatter light. Its exceptional properties make it an ideal filler material, enhancing the performance characteristics of products in various industries. For instance, in the paint and coatings market, TiO2 provides superior coverage and contributes to the longevity and durability of coatings. In plastics, it improves opacity and weather resistance, while in paper, it enhances brightness and smoothness.

Market Dynamics

The titanium dioxide industry is characterized by a diverse range of suppliers that cater to different market needs. These suppliers can vary from large multinational corporations to specialized niche manufacturers, each bringing unique advantages to the table. Large suppliers often have the capacity to produce high volumes of titanium dioxide and invest in advanced technology and research, ensuring consistent quality and supply stability.

On the other hand, smaller suppliers might focus on specific grades or variations of TiO2, catering to customers with particular needs. This specialization can serve niche markets, providing tailored solutions that larger manufacturers may overlook. The ability to respond quickly to changing demands and provide personalized service can give smaller suppliers a competitive edge.

Key Suppliers in the Industry

titanium dioxide filler suppliers

Globally, several key players dominate the titanium dioxide market. Companies such as DuPont, Tronox, and Cristal are recognized leaders known for their extensive product lines and robust distribution networks. These suppliers invest heavily in research and development to innovate and improve their products continually, addressing sustainability concerns and regulations that govern the industry.

Emerging markets have also seen new entrants in the titanium dioxide supplier landscape, particularly in Asia-Pacific regions. Chinese manufacturers, in particular, have significantly increased production capabilities and focused on competitiveness through cost-efficiency and broader product offerings. As such, the global supply chain has become more complex, with suppliers in various regions vying for market share.

Trends Shaping the Industry

As the titanium dioxide filler industry evolves, several trends are shaping its future. One significant trend is the increasing demand for environmentally friendly products. The global push for sustainability has led many suppliers to explore the production of titanium dioxide using less harmful processes and incorporating recycled materials. This focus on sustainability not only meets regulatory requirements but also appeals to environmentally conscious consumers.

Another trend is the rise of innovative applications for titanium dioxide fillers. The development of new composite materials and coatings has opened up additional markets, particularly in the automotive and construction sectors. Suppliers are actively exploring these opportunities by collaborating with manufacturers to develop custom formulations that meet specific performance criteria.

Furthermore, digitalization is becoming a transformative force in the supply chain. Suppliers are leveraging technologies such as data analytics and artificial intelligence to enhance operational efficiency, improve customer engagement, and streamline logistics. This digital shift is not only optimizing existing processes but also enabling suppliers to better anticipate market trends and customer needs.

Conclusion

Titanium dioxide filler suppliers play a crucial role in meeting the growing demand for high-quality TiO2 products across various industries. As market dynamics change, suppliers must adapt by embracing sustainability, exploring innovative applications, and leveraging digital technologies. The future of the titanium dioxide filler market looks promising, driven by a mix of traditional strengths and modern advancements. For manufacturers and consumers alike, understanding the landscape of titanium dioxide suppliers is vital in making informed decisions that align with both performance objectives and environmental considerations.

-

China Lithopone in China Supplier – High Quality Lithopone ZnS 30% Powder for Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Company – Premium TiO2 Powder Supplier & Manufacturer

NewsJun.10,2025

-

Fast Shipping 99% Pure TiO2 Powder CAS 13463-67-7 Bulk Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Manufacturers High-Purity R996 & Anatase

NewsJun.10,2025

-

Lithopone MSDS Factories - Production & Quotes

NewsJun.10,2025

-

High-Quality Titanium Dioxide in Water Suppliers - China Expertise 60

NewsJun.09,2025