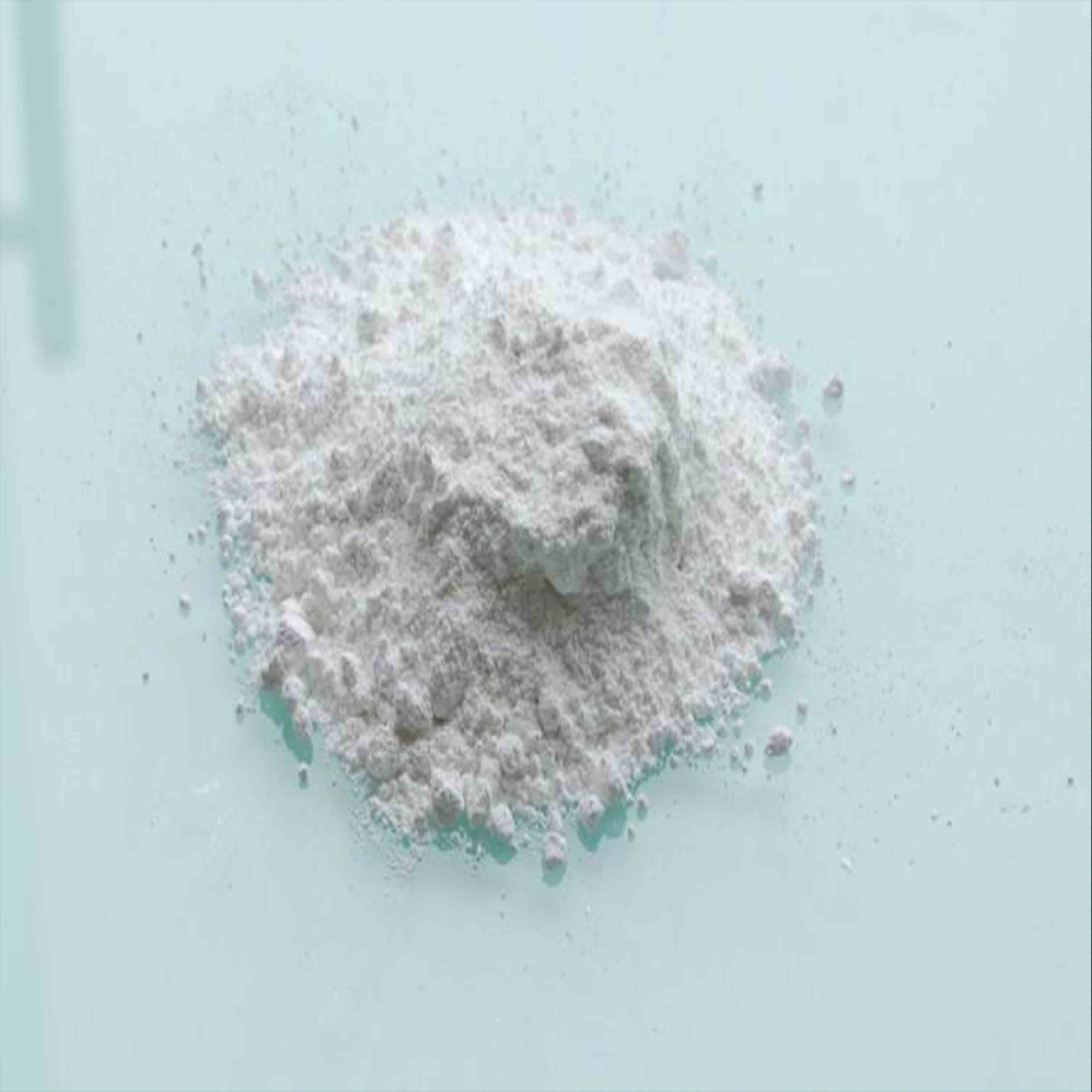

Industrial Titanium Dioxide with TIO2 >92% composition CAS 13463-67-7 Tio2

Jan . 25, 2025 05:54 Back to list

Industrial Titanium Dioxide with TIO2 >92% composition CAS 13463-67-7 Tio2

Titanium dioxide (TiO2) is a crucial component in various industries, revered for its properties as a pigment, sunscreen agent, and photocatalyst. With increasing demand driven by sectors like paints, coatings, and plastics, the TiO2 manufacturing industry has become both competitive and essential for modern technological advancements. At the heart of this industry are the manufacturers who blend expertise, innovation, and trust to deliver high-quality products worldwide.

Moreover, the authoritative stance of these manufacturers is often reflected in their commitment to research and development. Investing in R&D, these companies innovate to face global challenges, such as reducing the carbon footprint of TiO2 production and developing nano-TiO2 variants with unique properties. Their pioneering efforts in sustainability and product innovation not only help in gaining a competitive edge but also contribute significantly to the advancement of green technologies. Trustworthiness in the TiO2 manufacturing sector is also strengthened by transparent and ethical business practices. Leading manufacturers maintain clear communication channels with stakeholders, provide detailed product specifications, and ensure traceability from raw materials to finished products. By doing so, they not only comply with regulatory requirements but also build long-lasting relationships with clients and partners. A case study on success within this industry is Cristal (now part of Tronox), a global leader that has demonstrated expertise in both the sulfate and chloride manufacturing processes. Their integrated approach to sustainability, innovation, and community engagement showcases the multifaceted strategies that leading TiO2 manufacturers adopt to maintain their authoritative position in the market. In terms of product categories, manufacturers offer various forms of TiO2, including anatase and rutile grades, each engineered for specific applications. Anatase, with its excellent properties for UV absorption, is preferred in sunscreen formulations. In contrast, rutile, known for its higher opacity and weatherability, is a staple in the paints and coatings industry. The ability to produce these specialized products underscores the expertise of these manufacturers in addressing diverse industrial needs. Ultimately, the success of TiO2 manufacturers hinges on their ability to merge experience with innovation while maintaining their commitment to quality and ethical standards. As industries continue to evolve and demand more sophisticated materials, manufacturers who demonstrate proficiency, authoritative knowledge, and trustworthiness will remain indispensable contributors to the global supply chain. Through continuous improvement and strategic foresight, they ensure that titanium dioxide continues to be a cornerstone of industrial and consumer innovations.

Moreover, the authoritative stance of these manufacturers is often reflected in their commitment to research and development. Investing in R&D, these companies innovate to face global challenges, such as reducing the carbon footprint of TiO2 production and developing nano-TiO2 variants with unique properties. Their pioneering efforts in sustainability and product innovation not only help in gaining a competitive edge but also contribute significantly to the advancement of green technologies. Trustworthiness in the TiO2 manufacturing sector is also strengthened by transparent and ethical business practices. Leading manufacturers maintain clear communication channels with stakeholders, provide detailed product specifications, and ensure traceability from raw materials to finished products. By doing so, they not only comply with regulatory requirements but also build long-lasting relationships with clients and partners. A case study on success within this industry is Cristal (now part of Tronox), a global leader that has demonstrated expertise in both the sulfate and chloride manufacturing processes. Their integrated approach to sustainability, innovation, and community engagement showcases the multifaceted strategies that leading TiO2 manufacturers adopt to maintain their authoritative position in the market. In terms of product categories, manufacturers offer various forms of TiO2, including anatase and rutile grades, each engineered for specific applications. Anatase, with its excellent properties for UV absorption, is preferred in sunscreen formulations. In contrast, rutile, known for its higher opacity and weatherability, is a staple in the paints and coatings industry. The ability to produce these specialized products underscores the expertise of these manufacturers in addressing diverse industrial needs. Ultimately, the success of TiO2 manufacturers hinges on their ability to merge experience with innovation while maintaining their commitment to quality and ethical standards. As industries continue to evolve and demand more sophisticated materials, manufacturers who demonstrate proficiency, authoritative knowledge, and trustworthiness will remain indispensable contributors to the global supply chain. Through continuous improvement and strategic foresight, they ensure that titanium dioxide continues to be a cornerstone of industrial and consumer innovations.

Latest news

-

China Lithopone in China Supplier – High Quality Lithopone ZnS 30% Powder for Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Company – Premium TiO2 Powder Supplier & Manufacturer

NewsJun.10,2025

-

Fast Shipping 99% Pure TiO2 Powder CAS 13463-67-7 Bulk Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Manufacturers High-Purity R996 & Anatase

NewsJun.10,2025

-

Lithopone MSDS Factories - Production & Quotes

NewsJun.10,2025

-

High-Quality Titanium Dioxide in Water Suppliers - China Expertise 60

NewsJun.09,2025