Sep . 02, 2024 19:05 Back to list

Titanium Dioxide (TiO2) for Rubber Applications

The Role of TiO2 in Rubber Applications

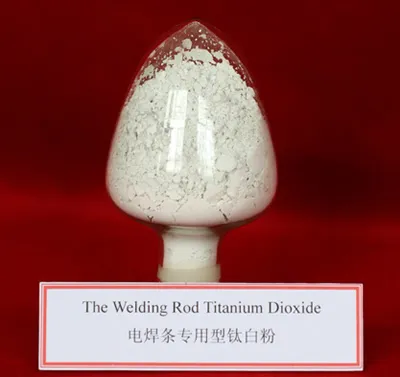

Titanium dioxide (TiO2) is a widely used compound in various industries, and its application in rubber manufacturing is of particular interest. This versatile substance, known for its excellent whiteness and UV resistance, plays a crucial role in enhancing the performance and aesthetics of rubber products.

The Role of TiO2 in Rubber Applications

In addition to its aesthetic benefits, TiO2 also contributes to the functional properties of rubber. It acts as a reinforcing agent, improving the mechanical strength and durability of rubber compounds. This is particularly important in tires and other high-performance rubber products, where resistance to wear and tear is paramount. The incorporation of TiO2 can also enhance the thermal stability of rubber, allowing it to maintain its integrity under varying temperature conditions.

tio2 used in rubber

Another significant advantage of TiO2 is its ability to provide UV protection. Rubber products that are exposed to sunlight for extended periods can suffer from degradation and discoloration. By adding TiO2, manufacturers can improve the longevity and reliability of their products. This UV resistance is critical in outdoor applications, such as roofing membranes and seals, where prolonged exposure to sunlight can lead to significant material breakdown.

Moreover, the use of TiO2 in rubber has implications for environmental sustainability. As industries increasingly seek eco-friendly materials, TiO2 offers a non-toxic option that does not compromise on performance. This characteristic is particularly beneficial in manufacturing products intended for consumer use, ensuring that they are safe for both people and the environment.

Despite its many advantages, the application of TiO2 in rubber does come with challenges. The handling and processing of the compound require careful management to avoid potential health risks associated with inhalation or dust exposure. Therefore, strict safety protocols are necessary during production to protect workers.

In conclusion, titanium dioxide serves multiple essential roles in the rubber industry, from providing a brilliant white pigment to enhancing mechanical strength and UV resistance. Its non-toxic nature aligns with the increasing demand for environmentally friendly materials. As research continues and technology advances, the potential applications of TiO2 in rubber will likely expand, offering even greater benefits to manufacturers and consumers alike.

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025