Nov . 11, 2024 11:55 Back to list

tinox tio2 factories

The Role of Tin Oxide and Titanium Dioxide Factories in Modern Industry

In today's fast-evolving industrial landscape, the significance of advanced materials cannot be overstated. Among these materials, tin oxide (SnO2) and titanium dioxide (TiO2) stand out due to their versatile applications and essential properties. Factories that specialize in the production of these compounds play a crucial role in various sectors, including electronics, coatings, and environmental applications.

Tin Oxide Properties and Applications

Tin oxide, a semiconductor material, is widely recognized for its exceptional electrical conductivity and transparency. These properties make it a valuable component in numerous applications. One of the most prominent uses of tin oxide is in the manufacturing of transparent conductive films, which are crucial for touch screens, solar cells, and liquid crystal displays (LCDs). As the demand for consumer electronics continues to surge, tin oxide factories are strategically positioned to cater to this burgeoning market.

Moreover, tin oxide’s photocatalytic properties are gaining traction in environmental remediation applications. Factories producing tin oxide nanoparticles are catering to the growing demand for solutions to combat air and water pollution. These nanoparticles can effectively break down organic pollutants when exposed to light, contributing to cleaner environments.

Titanium Dioxide The Multifaceted Compound

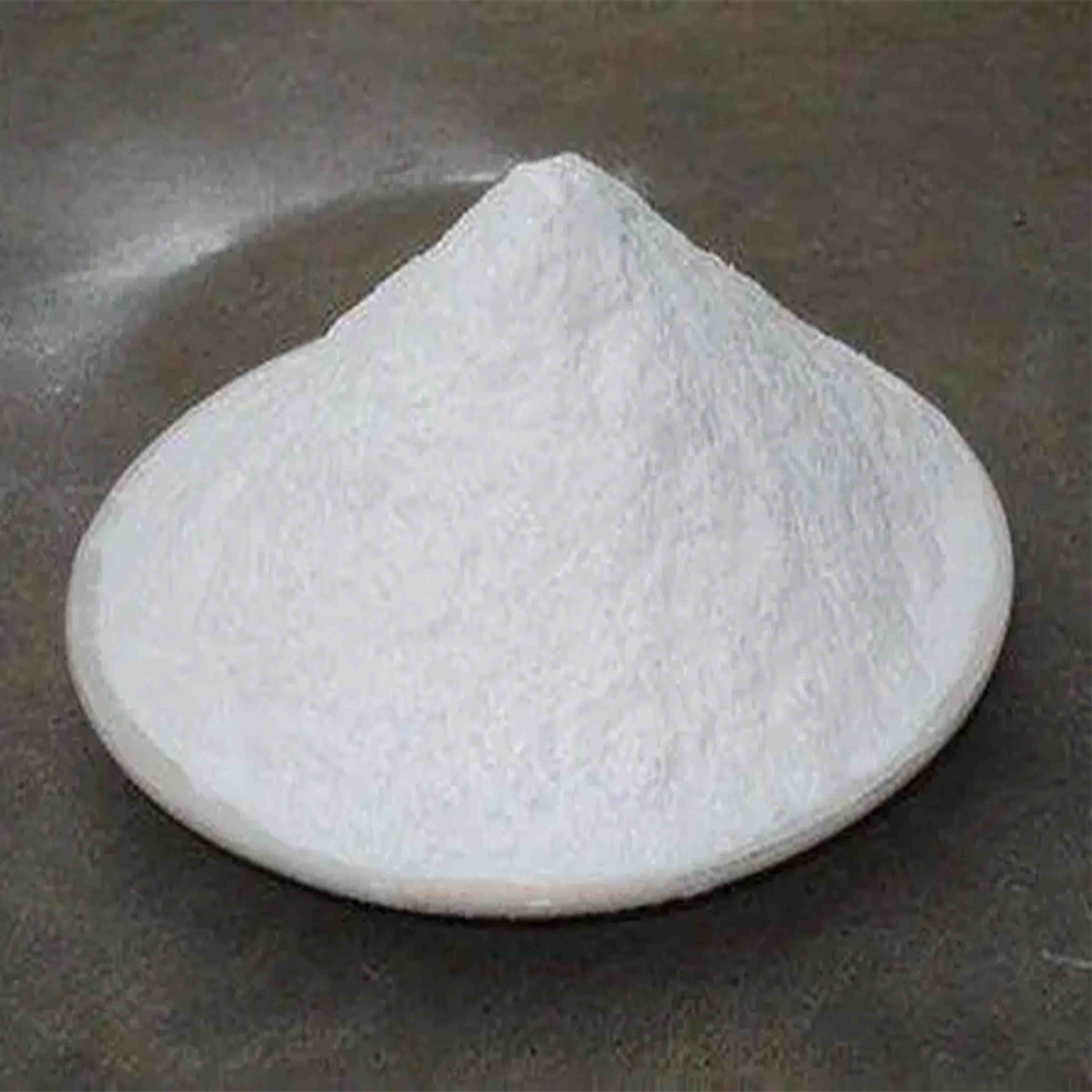

Titanium dioxide, on the other hand, is a widely used white pigment in the coatings, plastics, and paper industries. Its excellent opacity, brightness, and UV resistance make it an indispensable ingredient in paint manufacturing, providing durability and aesthetic appeal. The growth of the construction and automotive industries has further bolstered the demand for high-quality titanium dioxide products, leading to increased investments in TiO2 factories worldwide.

In addition to its role as a pigment, titanium dioxide is also employed in photocatalysis and as a sunscreen agent. Its ability to absorb UV rays while remaining non-toxic makes it a popular choice in cosmetic formulations, particularly in sunscreens. Factories focused on producing high-purity titanium dioxide are continuously innovating to enhance the quality and performance of their products, ensuring they meet stringent regulatory standards.

tinox tio2 factories

Technological Advancements and Sustainability

The production of tin oxide and titanium dioxide has also witnessed significant technological advancements. Modern factories are increasingly adopting eco-friendly manufacturing processes, minimizing waste and reducing energy consumption. Innovations such as hydrothermal synthesis and sol-gel methods are being employed to produce high-quality materials efficiently. These processes not only enhance the properties of the end products but also align with the global push for sustainability.

Moreover, the awareness of environmental concerns has led to a shift towards the development of recycling methods for these compounds. Tin oxide and titanium dioxide factories are exploring ways to recycle waste materials, reducing the environmental footprint associated with their production. This commitment to sustainability positions these factories as leaders in the movement towards greener industrial practices.

Challenges and Future Outlook

Despite the promising future for tin oxide and titanium dioxide factories, challenges remain. Fluctuations in raw material prices, particularly for titanium ores, can impact production costs. Furthermore, stringent regulations surrounding environmental sustainability are compelling factories to invest in cleaner technologies, which may require substantial capital expenditure.

However, the outlook for these factories remains optimistic. The continuous growth of the electronics and automotive sectors, coupled with the rising demand for eco-friendly products, is expected to drive the expansion of tin oxide and titanium dioxide production. As industries evolve, factories that innovate and adapt to changing market dynamics will be well-positioned to thrive.

Conclusion

In conclusion, tin oxide and titanium dioxide factories are integral to various facets of modern industry. Their contributions to electronics, coatings, and environmental applications underscore the importance of these materials in our daily lives. As technological advancements continue to shape the industry, these factories are poised to meet the evolving demands of the market while committing to sustainable practices. With a focus on innovation and environmental responsibility, the future of tin oxide and titanium dioxide production looks bright, promising significant contributions to both the economy and the planet.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025