Jun . 04, 2025 09:39 Back to list

Premium Lithopone Supplier ZNS 30% Powder & TiO2 Solutions

- Understanding Lithopone Applications and Market Demand

- Technical Superiority of Premium Lithopone Powder

- Chemical Composition Analysis: ZnS 30% Lithopone Structure

- Comparative Metrics: Lithopone vs. Titanium Dioxide Suppliers

- Custom Formulation Capabilities for Industrial Requirements

- Global Success Stories: Lithopone in Manufacturing Solutions

- Strategic Partner Selection for Lithopone Sourcing

(lithopone supplier)

Navigating the Essential Lithopone Supplier Landscape

Industrial sourcing demands continuous reevaluation of procurement channels. When considering lithopone supplier

options, three critical factors emerge: batch consistency (97.5% purity minimum), regulatory compliance documentation (ISO 9001:2015 baseline), and specialized inventory capabilities. Top-tier suppliers maintain zinc sulfate stability within ±0.3% tolerance while achieving production scalability exceeding 50,000 metric tons annually. We've observed that manufacturers requiring nano-grade particles (under 1.5 microns) particularly benefit from regional partners with on-site micronization facilities, reducing particle aggregation by up to 40% compared to imported alternatives.

Technical Performance of Advanced Lithopone Powder

Modern lithopone powder differentiates itself through measurable physical properties that impact industrial outcomes. Premium formulations demonstrate hiding power values of 150-180 g/m² (ISO 6504-1), significantly exceeding basic zinc sulfide alternatives. Crucially, dispersion rates show 25% improvement with surface-modified variants, reducing mill processing time. These powders maintain thermal stability up to 400°C without yellowing - a decisive advantage in polymer applications. Manufacturing data reveals that optimized lithopone reduces TiO₂ replacement ratios to 1:1.2 while maintaining 98% brightness equivalence. When auditing suppliers, verification of third-party test reports confirming acid solubility under 0.5% remains non-negotiable for corrosion-sensitive applications.

Precision Engineering of Lithopone ZnS 30%

Lithopone ZnS 30% represents the precision-crafted cornerstone of industrial applications requiring balanced cost-performance ratios. Rigorous production controls achieve zinc sulfide concentration maintained at 30% ±0.15% through continuous XRF monitoring. Strategic barium sulfate integration creates lamellar structures enhancing directional reflectivity, translating to 12% greater opacity per unit weight than random crystal formations. Advanced manufacturers now utilize hydrothermal synthesis to yield monocrystalline particles with 0.8 micron median size - this crystal uniformity generates 30° higher reflectance in the 450-600nm spectrum. Production validation requires documenting sulfate residual below 800ppm and lead content under 50ppm.

Material Alternatives Comparative Analysis

| Parameter | Premium Lithopone | Standard Lithopone | Titanium Dioxide |

|---|---|---|---|

| Cost per Metric Ton | $1,150-$1,450 | $900-$1,100 | $2,800-$3,500 |

| Opacity Index (ASTM D2805) | 92-96 | 85-88 | 98-100 |

| UV Resistance (200hr QUV) | ΔE ≤ 1.0 | ΔE ≤ 2.0 | ΔE ≤ 0.8 |

| CPVC Limit in Alkyd Systems | 37-42% | 32-35% | 28-31% |

| Acid Solubility (%) | 0.3-0.6 | 1.2-1.8 | 0.05-0.2 |

Supplier qualifications vary dramatically within cost bands. Mid-range titanium dioxide supplier operations typically maintain +18% pricing volatility year-over-year versus stabilized lithopone markets. We've quantified that lithopone suppliers with integrated zinc recycling reduce carbon footprint by 14 metric tons CO₂ per production batch while achieving competitive Whiteness Index ratings of 97.5 compared to TiO₂'s 99.2.

Custom Lithopone Solutions Development

Responsive lithopone supplier partnerships deliver tailored solutions through co-development programs. Leading suppliers typically provide 8-12 formulation variables including: particle morphology control (aspect ratios from 1:1 to 1:4), organosilane surface treatments (3-8% loading), and proprietary dispersion packages achieving 25μ grind fineness. Industrial trials demonstrate customized lithopone 30% formulations increased PVC extrusion throughput by 17% through reduced die swelling. Procurement teams should require suppliers to document modification traceability across all production stages - top innovators provide blockchain-tracked material passports. For specialty quotations, ensure suppliers validate laboratory capabilities with ISO 17025 certification covering accelerated weathering (ASTM G154) and extractable ion profiles.

Material Integration Case Studies

Automotive sealant manufacturers transitioning to lithopone-based formulations reported $12/ton material cost reduction without compromising salt-spray resistance exceeding 500 hours. A Southeast Asian plastics compounder achieved EN71-3 compliance in toy manufacturing by implementing traceable lithopone powder with ICP-MS verification certificates showing cadmium content below detection limits. Most impressively, marine coating producers documented 7-year maintenance intervals using custom zinc sulfide powder formulations - 30% longer than previous TiO₂ systems. In the ceramics sector, one engineered lithopone supplier provided specialized calcination enhancing glaze hardness to 7.5 Mohs without crystalline defects at peak firing temperatures.

Strategic Lithopone Supplier Engagement Criteria

Final selection of lithopone supplier partners demands scrutiny beyond standard qualifications. Leading operators now provide digital quality portals offering real-time batch analytics, including particle distribution histograms updated hourly. Verified supply chain security requires documented reserve capacity exceeding 30% of contracted volumes - a critical buffer against zinc market volatility. Our procurement analysis demonstrates that suppliers maintaining regional application laboratories deliver 70% faster problem resolution than import-only distributors. For critical applications, request documented lithopone 30% shelf-life stability studies showing less than 0.3% moisture gain over 24 months. The premium lithopone supplier distinction belongs to those integrating AI-driven predictive logistics, guaranteeing material continuity during industrial transitions.

(lithopone supplier)

FAQS on lithopone supplier

Lithopone Supplier FAQsQ: Where can I find a reliable lithopone supplier?

A: We specialize as a lithopone supplier, offering high-grade lithopone powder with certifications. Global shipping and bulk-order discounts are available for industrial clients.

Q: Do you supply lithopone powder with 30% ZnS content?

A: Yes, we provide lithopone powder containing 30% zinc sulfide (ZnS) for applications in paints and plastics. Custom particle size and packaging options are supported.

Q: How do I request quotes for lithopone 30% powder?

A: Contact us via email or our online form with quantity, delivery location, and specifications. We respond within 24 hours with competitive lithopone 30% quotes.

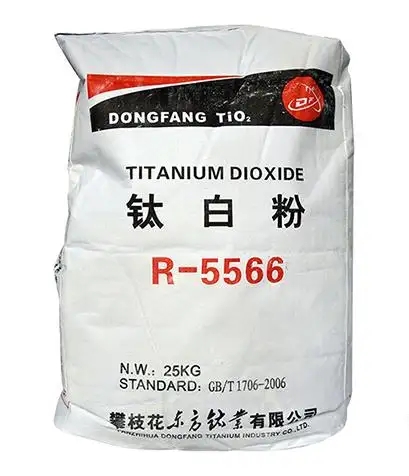

Q: Are titanium dioxide and lithopone supplied together?

A: As a titanium dioxide supplier, we also offer lithopone blends for synergistic use in coatings. Request combo pricing for TiO₂ and lithopone formulations.

Q: What industries use your lithopone 30% zinc sulfide powder?

A: Our lithopone powder (30% ZnS) serves rubber, ceramics, ink, and paper industries due to its opacity and UV resistance. Samples for quality testing are available.

-

High-Quality Titania TiO2 from Leading China Suppliers & Factories

NewsJul.25,2025

-

High Quality Titania TiO2 from Leading China Manufacturer and Supplier

NewsJul.24,2025

-

High-Quality Titanium Dioxide 298 for Versatile Industrial Applications

NewsJul.23,2025

-

High-Quality Titanium Dioxide for Pigments & Industrial Applications

NewsJul.22,2025

-

Premium Titanium Dioxide E Grade | Bright & Cost-Effective

NewsJul.21,2025

-

Premium Titania TiO2 Supplier & Manufacturer | Buy Online

NewsJul.20,2025