Des . 04, 2024 23:35 Back to list

estimation of sulphate as titanium dioxide manufacturer

Estimation of Sulphate as Titanium Dioxide Manufacturer

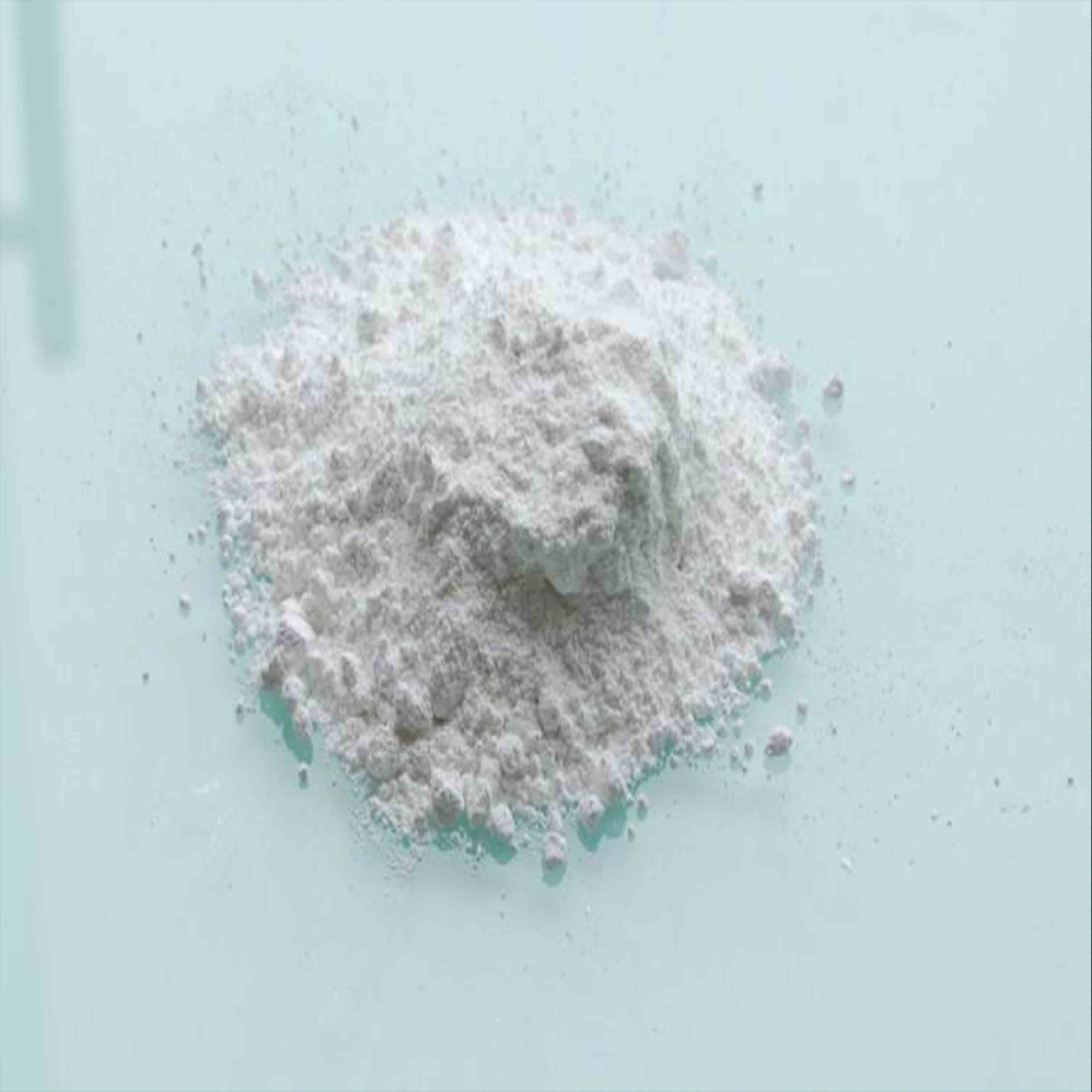

In the manufacturing industry, precision is paramount, particularly when it comes to the production of chemical compounds such as titanium dioxide (TiO2). Titanium dioxide is extensively used in various applications, including paints, coatings, plastics, and even food products, owing to its excellent pigmentary properties and UV resistance. However, one aspect that often gets overlooked is the estimation of sulphate content within titanium dioxide production processes. Understanding how to manage and estimate sulphate is crucial for maintaining product quality and compliance with industry standards.

Importance of Sulphate Estimation

Sulphate content can significantly affect the performance characteristics of titanium dioxide, particularly when it comes to its stability and usability in different applications. High levels of sulphate can lead to issues such as decreased resistance to weathering, alterations in the pigment's opacity, and even impact the reactivity in various chemical formulations. Thus, accurate estimation is essential not only for adhering to regulatory standards but also for ensuring customer satisfaction and achieving market competitiveness.

Methods of Estimating Sulphate Content

There are various methods employed in the industry to estimate sulphate content in titanium dioxide. Common techniques include gravimetric analysis, ion chromatography, and spectrophotometry.

1. Gravimetric Analysis This is one of the oldest and most reliable methods for estimating sulphate. The procedure involves precipitating the sulphate as barium sulphate (BaSO4) and weighing the resulting precipitate. While this method is highly accurate, it is also labor-intensive and time-consuming.

2. Ion Chromatography This modern technique is renowned for its sensitivity and speed. Ion chromatography allows for the separation of ions and is particularly effective in identifying and quantifying anions like sulphate. It is a preferred method in many laboratories for routine analysis due to its high-throughput capabilities.

estimation of sulphate as titanium dioxide manufacturer

3. Spectrophotometry This method involves measuring the absorbance of a sulphate solution at a specific wavelength. It is often used in conjunction with a calibration curve established using known sulphate standards. Although this method is less precise than gravimetric analysis, it is much simpler and quicker.

Each of these methods has its advantages and drawbacks, and the choice of technique often depends on factors such as required accuracy, available equipment, and specific industry requirements.

Challenges in Estimation

Estimating sulphate content in titanium dioxide production poses challenges. For instance, the presence of other ions may interfere with the accuracy of the measurements. Contaminants from raw materials can also complicate the sulphate estimation process, leading to discrepancies in product quality.

Moreover, as environmental regulations tighten globally, manufacturers are under pressure to minimize contaminants in their products. This has necessitated the development of tighter quality control measures and more rigorous testing protocols, making accurate sulphate estimation more critical than ever.

Conclusion

In conclusion, the estimation of sulphate content in the manufacturing of titanium dioxide is a crucial process that cannot be understated. Given its significant impact on product quality and regulatory compliance, manufacturers must prioritize accurate measurement techniques. Whether utilizing gravimetric analysis, ion chromatography, or spectrophotometry, being equipped with the right tools and knowledge can lead to enhanced product reliability and customer satisfaction.

As industries continue to evolve, so too will the methods for estimating impurities like sulphate. Emphasizing continuous research and adopting innovative practices will not only uphold product standards but will also pave the way for the sustainable advancement of titanium dioxide production in the years to come. With a focus on quality, manufacturers will not only meet regulations but also foster trust and loyalty among their clients, ensuring a successful future in a competitive market.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025